3D printing / additive manufacturing for product development

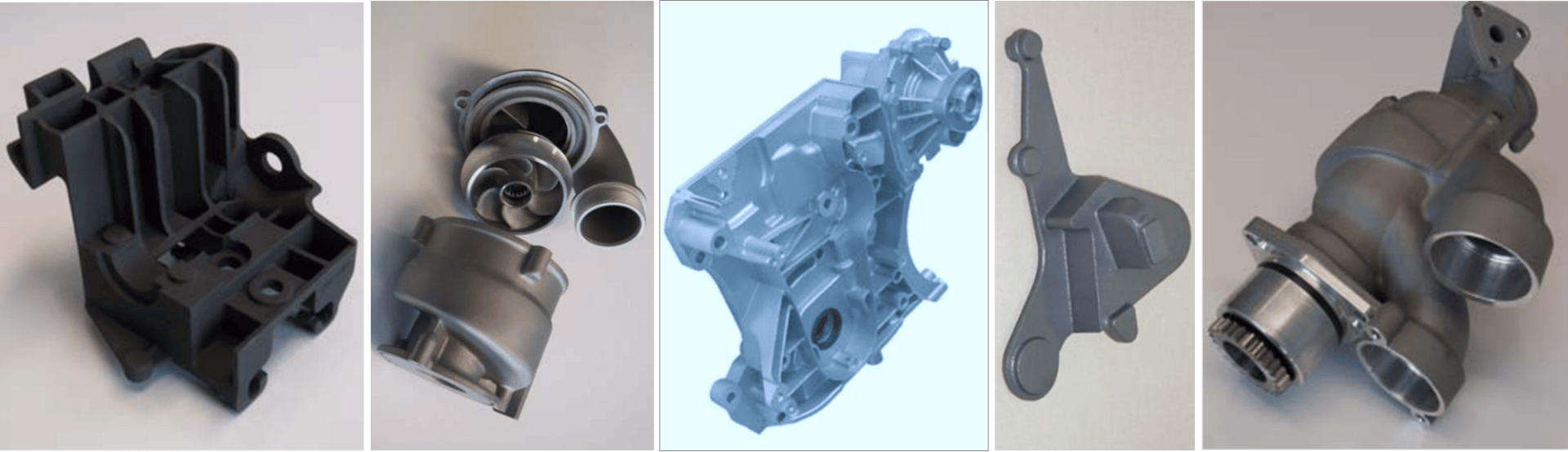

We combine modern 3D printing techniques with proven metal and plastic casting techniques. Thus, we support the individual phases of the product development process with a sustainable approach of 'creating only what is necessary for development evaluation at any given time.'

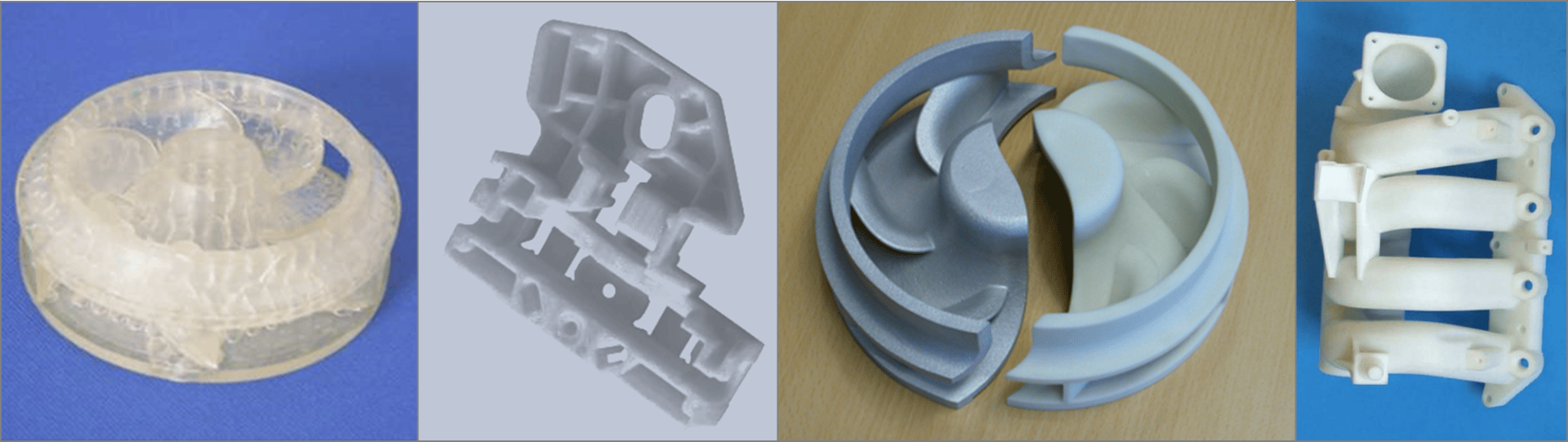

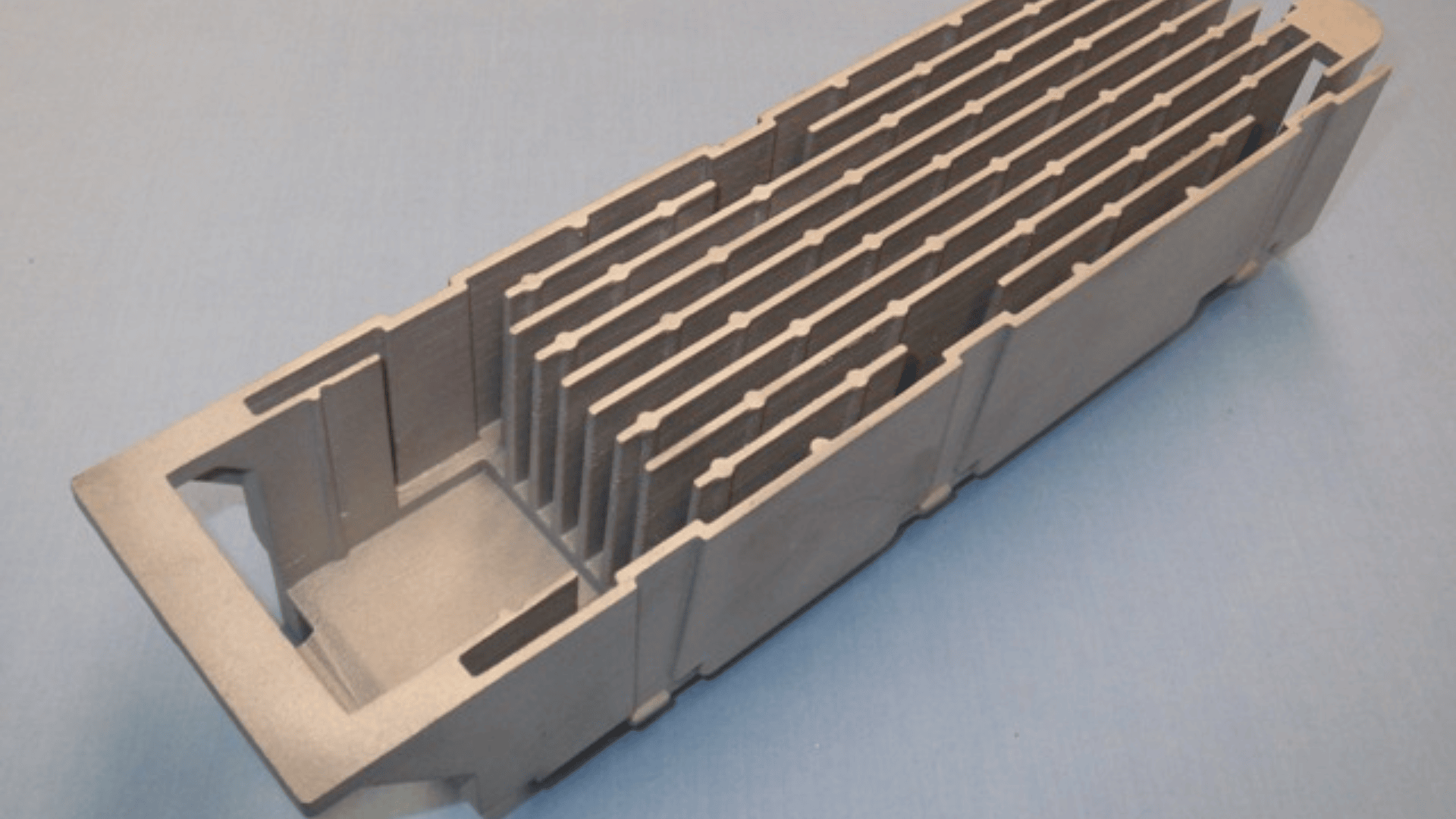

Many models which are used within development processes are generated by using additive technologies. At PORTEC are available: stereo lithography machines with gas- or solid state laser, the Fused Deposition Modeling (FDM)-technology and the 3d-printing powder-binder-system.

Stereo Lithography parts can be manufactured in different accuracies, hollow or light-weight, and can also be heat-treated for higher thermal strength. 3d-powder-binder parts consist of PMMA and can additionally be infiltrated with a special plastic material system. Thus these parts reach properties for the use as conceptual models and partial of functional parts. Using the FDM process, very complicated geometric details can be built even in such stout materials like ABS, ABS-PC-blend up to metal even ceramic.