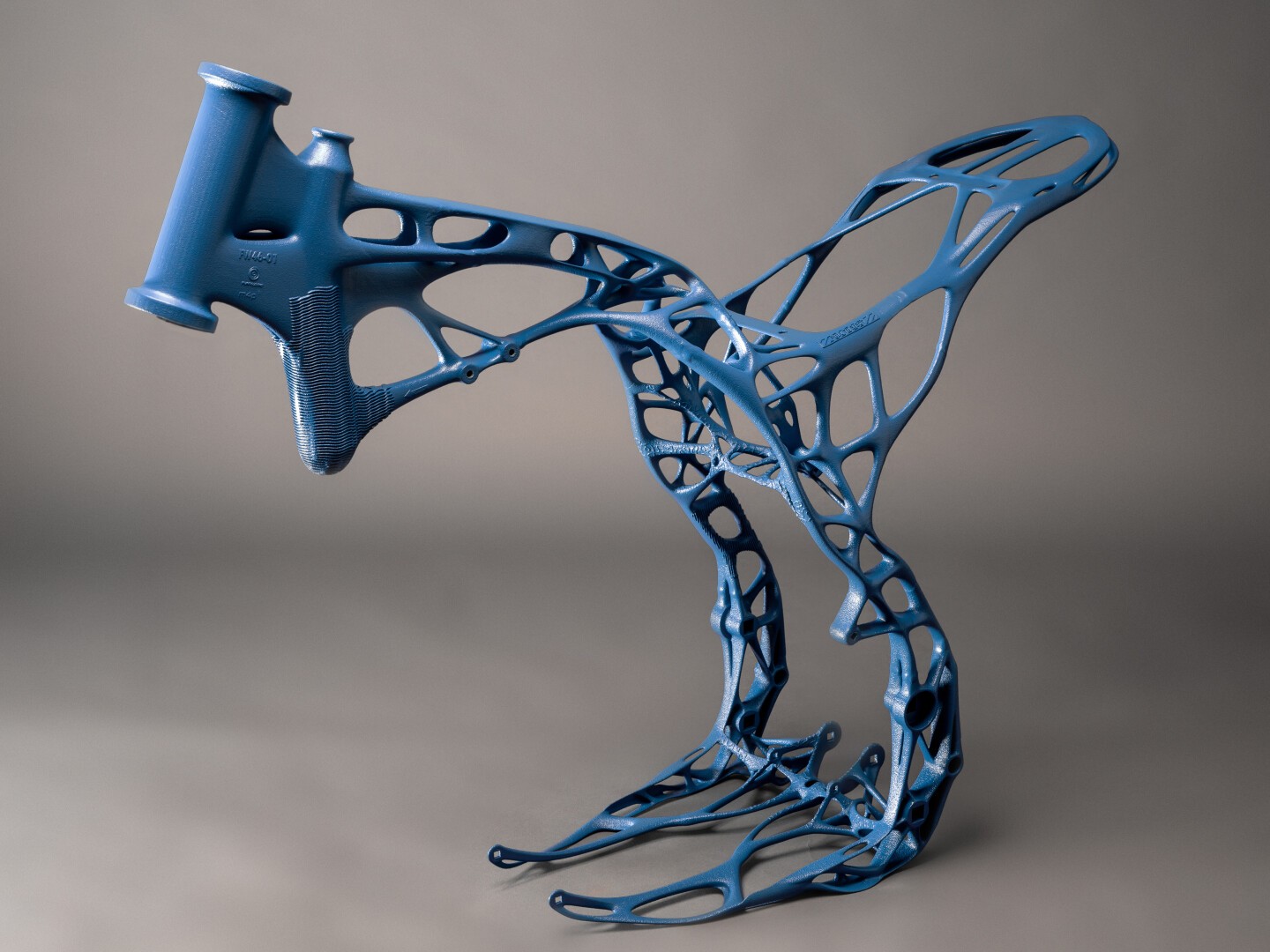

Additive manufactured ultralight motorcycle frame enabled by m4p™ AlSi10Mg

How did we use AlSi10Mg to successfully 3D print a motorcycle frame and what advantages did this bring? Find out in the following CaseStudy, also available in our webshop.

Context

The focus of the collaboration with PUNTOZERO 3D, a company specialized in design for additive manufacturing, was to investigate the advantages of metal additive manufacturing for producing a motocross frame. The aim was to develop a new frame design and to realize it in an appropriate material so that as few components as possible need to be manufactured and the overall result is lighter and stiffer than its conventionally manufactured counterpart.

Approach

The frame was made with a honeycomb structure which made it possible to simultaneously obtain lightness and stiffness. The team also used topology optimization to identify areas of the frame that could be made thinner or removed to reduce weight. To produce the frame, EOS M400-1 3D printer with m4p™ AlSi10Mg material was used. This additive manufacturing process has made it possible to create a complex structure with high precision, something that would have been impossible to achieve with traditional manufacturing methods.

Results

The new frame design has proven to be very effective, with several advantages over the original design:

1. Weight reduction: The original frame weighed 18kg, while the new frame weighs less than 6,52kg, resulting in a 63% weight reduction.

2. Same stiffness: Despite being 63% lighter, the new frame has maintained the same stiffness as the original design.

3. Simplified assembly: The new frame design required only 5 parts, compared to 21 parts for the original design. This reduction in the number of parts has simplifi ed the assembly process and reduced

the risk of errors or defects.

4. Material: The original frame was made of steel, while the new frame was made of m4p™ AlSi10Mg material, a lightweight aluminum alloy that is commonly used in additive manufacturing. The use of this material has further reduced the weight of the frame while maintaining its strength.

Conclusions

The company’s decision to explore the benefi ts of additive manufacturing paid off, leading to a successful new motocross frame design.