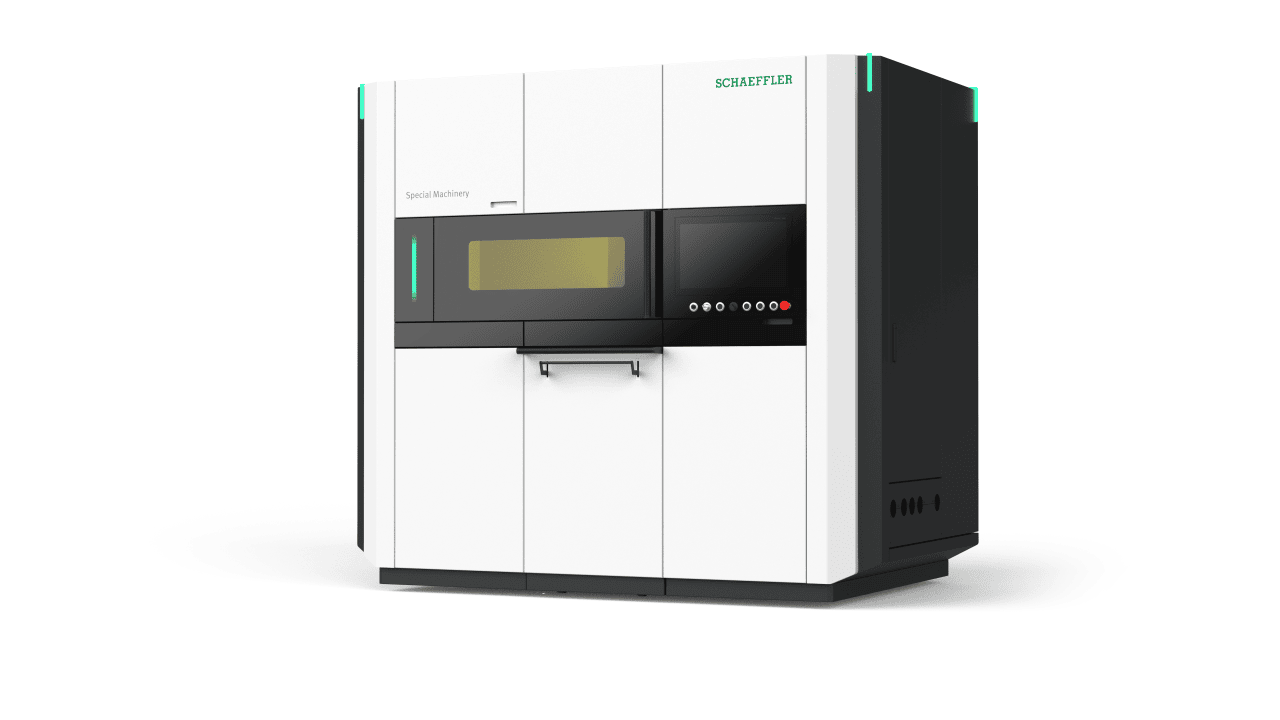

The innovative solutions from Schaeffler Aerosint Sa and the decades of industrialization know how of Schaeffler Special Machinery merge into extended customer value add. Our new system, called OmniFusion 3D, will be a benchmark for the industrial application of metal multi-material AM.

Selective powder deposition

Schaeffler Aerosint SA is a specialist in innovative additive manufacturing technologies. Since October 2023 Aerosint is 100% part of Schaeffler and part of the Schaeffler Special Machinery network. As leading company for multi-material applications, Schaeffler Aerosint SA is a key player to unlock the possibilities of new material combinations.

Automation & industrialization

With more than 70 years of experience in production we at Schaeffler Special Machinery are experts for innovative manufacturing turnkey solutions — all-in-one from the idea and the development through to the design and implementation of the machines.

Holistic production solutions

Combining the core competencies of Schaeffler Special Machinery and Schaeffler Aerosint SA we are reaching a milestone for additive manufacturing. Our new system, called OmniFusion 3D, will be a will be a benchmark for the industrial application of metal multi-material additive manufacturing.

The innovative solutions from Schaeffler Aerosint Sa and the decades of industrialization know how of Schaeffler Special Machinery merge into extended customer value add.

Our goal is to take a holistic approach - from the design of the 3D geometry to the ready-to-use component. We ensures seamless integration into existing production workflows, from conception to fabrication. Going beyond conventional boundaries, we combine cutting-edge technology with extensive expertise to accelerate product development and meet individual needs.

Our 3D-multimaterial additive manufacturing system empowers you for

- unique material combinations

- innovative functional integration in products & tools

- flexibility in design for individual, free design of products & tools

- fast response to changing market requirements and designs

- Reduced lead time, especially for tools & prototypes

The „printing“ process

involves the deposition of material on the print bed in layers. Our innovative technology enables the use of up to three different materials, which are supplied by integrated powder reservoirs into the recoater. There, the material powders are arranged pixel-wise on the build platform and deposited layer by layer. During the scanning step, the part is created. Multiple laser sources and scanners can be used to process a wide range of materials efficiently, like metals or ceramics. The printing process itself takes place in a sealed process chamber, filled with argon inert gas.

In cooperation with our partners,

we offer a comprehensive range of services, including the machine, the corresponding software, and the provision of the printing material.

In addition, we provide complementary services such as „Design to Additive“, supporting our customers in the design of their 3D models, as well as services around measuring and calibration to ensure that the 3D manufactured products are of high quality and reliably produced by our machine.