Combining the best of two worlds: How Mold One Flex brings PU foam components into perfect shape

There is a multitude of different applications for PU foams across all industries. However, conventional toolmaking imposes relatively strict limits on design. The solution: Mold One Flex uses intricate 3D-printed disposable molds that are filled with commercially available PU foams.

To this day, the choice of available materials has been a limiting factor for the additive manufacturing of components. However, material development has seen a significant upturn in recent years thanks to the entry of major material manufacturers into the field. But sometimes it’s also a creative detour that leads to the goal, as shown by the technology "Mold One Flex" for PU foams. Although shaped foams are still almost impossible to produce additively, foam components can also be produced in intricate geometric shapes by using a 3D-printed disposable mold. And for this disposable mold, there are indeed innovative new materials!

The requirements for such a disposable mold are that it must be produced quickly and cost-effectively, that the material can withstand the pressure and temperature of the foam reaction and, last but not least, that the mold is so brittle that it can be easily removed from the finished component by a simple crushing step. The process that ideally fulfills these requirements is the new MSLA process (Masked Stereolithography Apparatus), which ensures very good surfaces with good details.

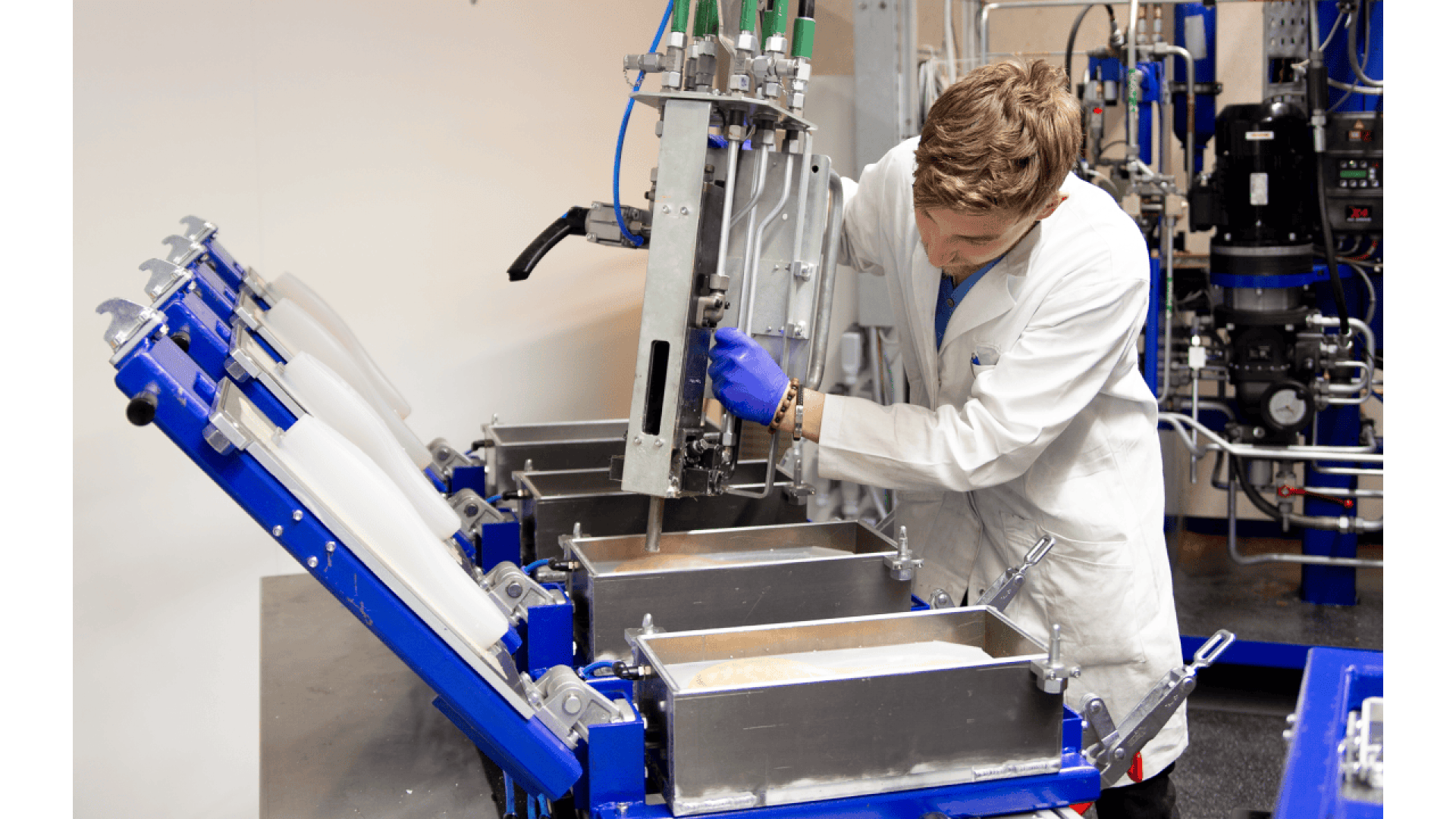

Mold One Flex uses liquid PU materials such as isocyanate and polyol for foaming. The reaction mass foams up in the mold of the high-pressure foaming system at a pressure of 0.8 bar. The mold and component then cure in a heating oven. The foam density can be controlled very well depending on the mixing ratio.

The special feature of the Mold One Flex hybrid process is the combination of innovative additive and proven conventional manufacturing methods. A one-off mold is produced for each component using the MSLA process. MSLA materials have the advantage that the molds can be produced quickly, cost-effectively, individualized, and with high capacities. They can be removed from the component very easily by a crushing process due to the brittle material properties.

PU foams have an excellent insulating and damping effect and are ideal for individualized mass products such as shoe soles, upholstery, and impact protection. One example of the use of Mold One Flex is the prototype of an armrest.

First, a hollow mold is printed with MSLA. The high level of detail (e.g. finely structured) and the high surface quality (e.g. smoothly ribbed) of the foam mold determine the surface quality of the subsequent foam part. A 3D-printed inner frame (e.g. selective laser sintering, SLS) is inserted into the mold as an inlay for increased stability of the armrest. A cross-lattice structure (the so-called "body-centered cubic" structure) ensures a firm connection between the hard inner core and the later soft foam padding. The cavity between the outer mold and the insert is then filled with polyurethane foam in the traditional way. A pressure of 0.8 bar ensures the desired foam density. The part is dimensionally stable after 8 minutes. The component then hardens in the mold in a heating oven at 33 °C. Once the foam cushion has hardened, the disposable mold is crushed and the splinters of the extremely brittle material can be removed by simply tapping it off. By destroying the mold, the geometric restrictions that otherwise apply to molds, such as undercuts, are no longer relevant.

There is no further post-processing needed. The product is ready after the mold has been removed. Compared to injection molding, Mold One Flex has the advantage of all-round clean surfaces without sprues and burrs. Individual inscriptions and tracking codes with a high level of detail can be easily applied to any component thanks to the 3D-printed disposable mold, and the restrictions on de-moldability that apply to injection molding are eliminated.

Mold One Flex combines the advantages of classic molded foam parts with a new degree of design freedom and an even faster, process-reliable production in higher lot sizes. That’s why this hybrid process is an exciting addition to the additive manufacturing inventory; it will not make injection molding obsolete, obviously, but it is a valuable addition to the industrial manufacturing toolbox for specific projects.