Driving Large-Scale Advancement in Metal 3D Printing Industry

With advancements in capacity and sophistication at scale we have seen ever greater adoption of 3D printing by modern manufacturing looking at serial production. Key to the rise of 3D printing is the advancement in materials such as metal powders.

The quality and price points of metal powders form a fundamental part of increasing adoption for multiple industries where uptake is growing. As part of our goal to commercialize and promote the industry, CNPC Powder is honored to participate in Rapid-Tech 3D, showcasing our latest research and development achievements and innovative ideas in the field of AM.

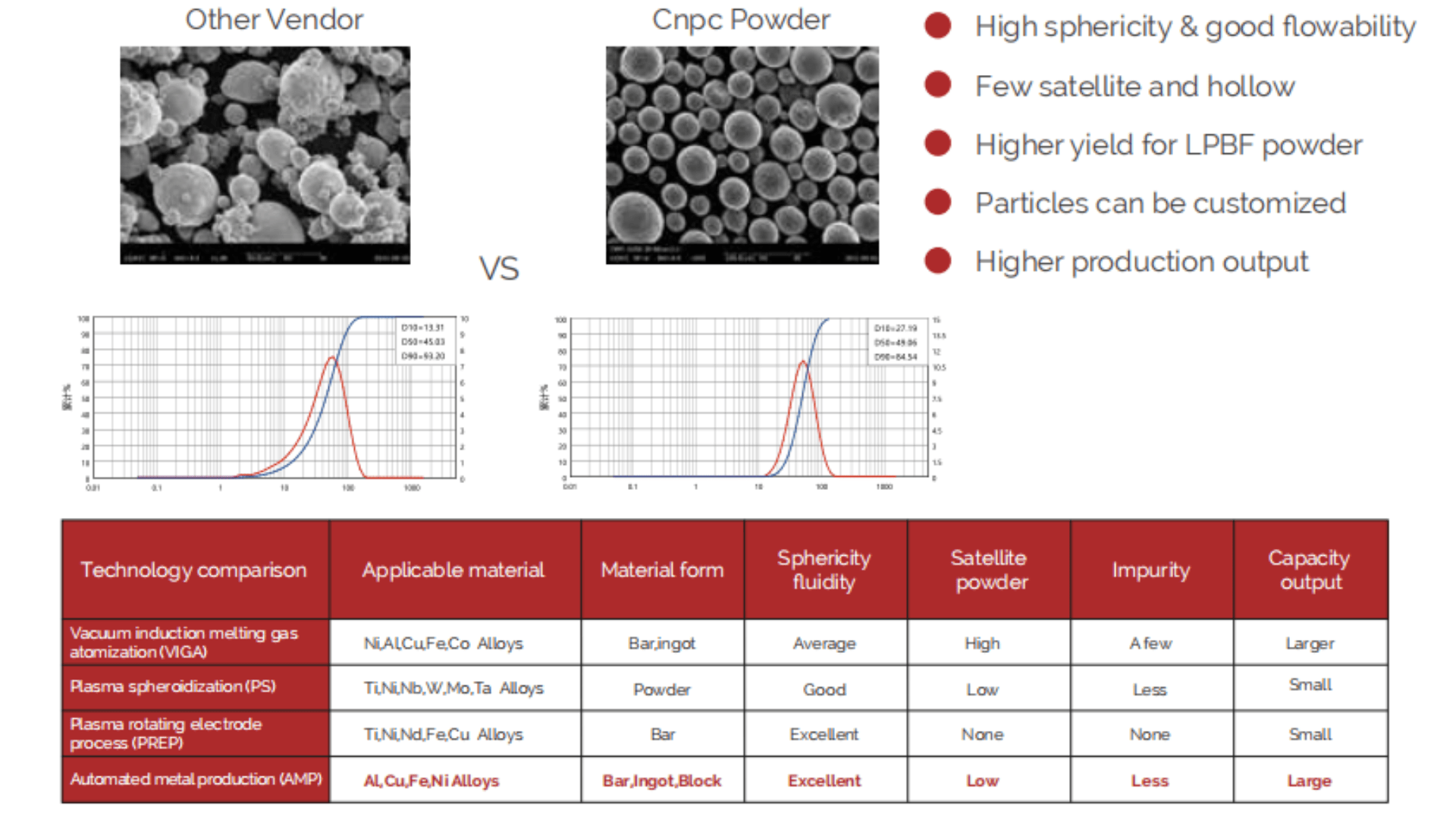

High Quality Low Cost Automated Metal Production -(AMP lines)

We have taken a special focus since our inception on materials development, as a driver for improving the uptake of AM technology. Through years of technological advancements and experience on the ground, we successfully developed our AMP production line with independent intellectual property rights in 2019. This cutting-edge production line adopts advanced manufacturing techniques to produce metal powders with high sphericity and exceptional performance, all while maintaining high yield, low gas consumption, and improved cost-effectiveness. AMP offers metal powder users a very high quality powder with a low barrier to entry for the large-scale application of 3D printing in various industries.

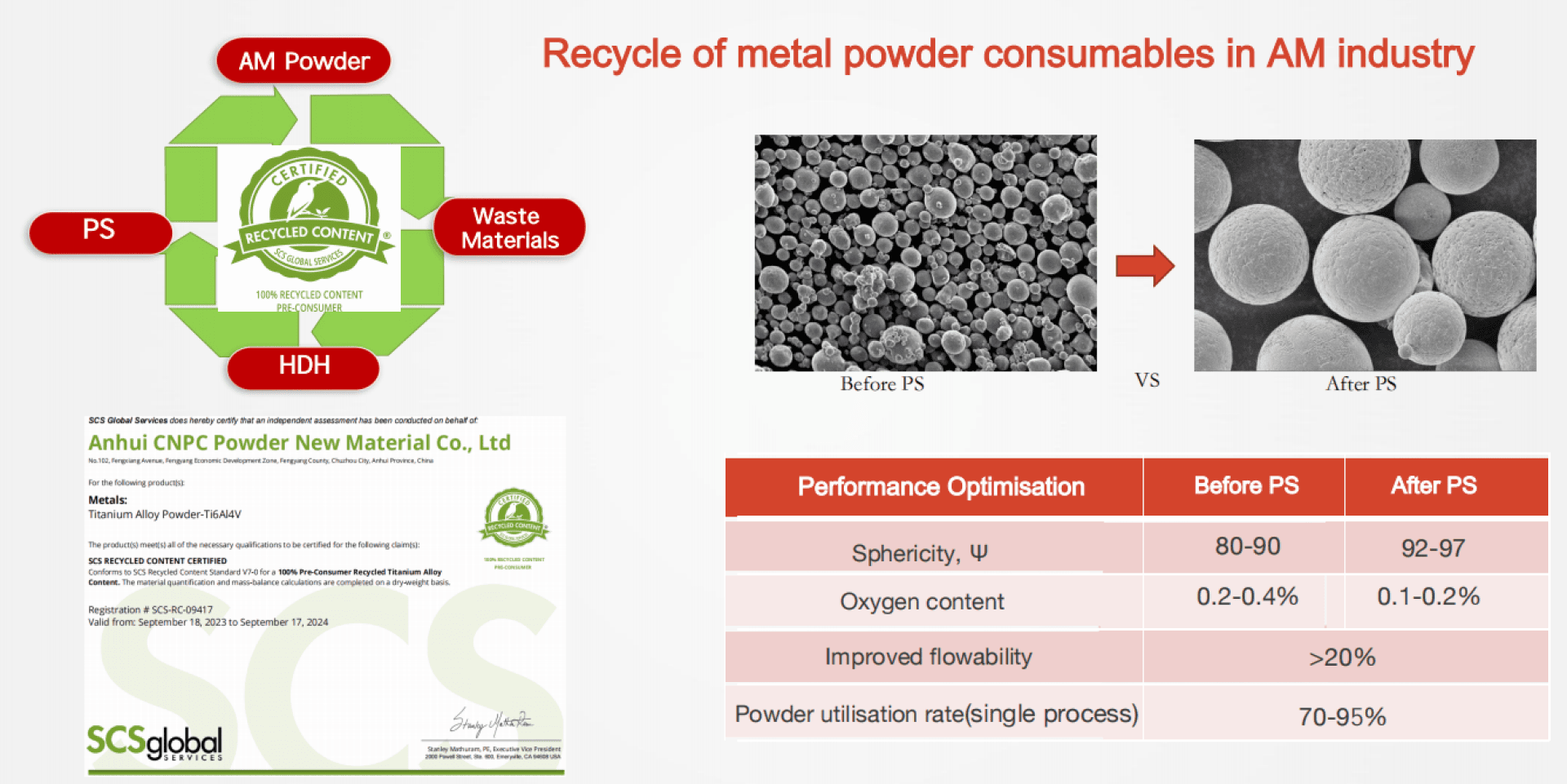

Loop Manufacturing In AM Industry Recycling Materials Production

For large-scale applications, titanium alloy powder’s cost remains a significant barrier to entry and adoption. However, CNPC POWDER is working here to reduce the cost of powder as a sustainable source for advanced manufacturing. We are achieving this through the deployment of our advanced technology to recycle turnings and offcut scrap and produce a high-quality AM Titanium alloy powder. Our process will significantly reduce the cost of metal 3D printing powder materials while expanding the life cycle of materials. As a green alternative to traditional titanium alloy powder sources, it offers more possibilities for expanding 3D printing applications, and reduces the carbon footprint of all parts of the value chain.

In September 2023, CNPC Powder was the first 3D printing metal powder manufacturer in China to obtain our 100% titanium alloy recycled material SCS certification. Through a comprehensive analysis of the product life cycle, our process’ carbon emissions during the production amount to only about 10% of the traditional EIGA production process. Given this advancement, the environmental benefits are obvious. Using recycled raw materials can not only reduce the material’s carbon footprint as well as potentially save costs. The efficiency of our closed-loop system can ensure the security of the supply chain and promote the sustainable development of the environment and economy. With the establishment of a closed loop (or circular metal economy) between strategic producers and their supply chains, we are able to maximize affordability advantages while also ensuring quality and sustainability long term.

Formulas of multiple new high-strength and high-temperature resistant aluminum alloy materials

CNPC Powder works closely with leading domestic and international institutions and works to rapidly understand our customers' most challenging needs. We then work in collaboration with our customers and industry partners to develop and iterate multiple high-strength aluminum and high-temperature resistant aluminum alloy material formulations. These materials meet the performance requirements of downstream application scenarios, especially suitable for lightweight and other application scenarios. We invite you to check out our catalogue and reach out to one of our experts. We are always happy to connect with you to tackle your toughest challenges.