Next Evolution in Additive Production – CAMS

In September 2017, Farsoon Technologies first introduced the Continuous Additive Manufacturing Solution (CAMS) concept addressing the growing movement of the laser powder bed fusion additive manufacturing industry from rapid prototyping into series volume production.

Continuous Production Capable

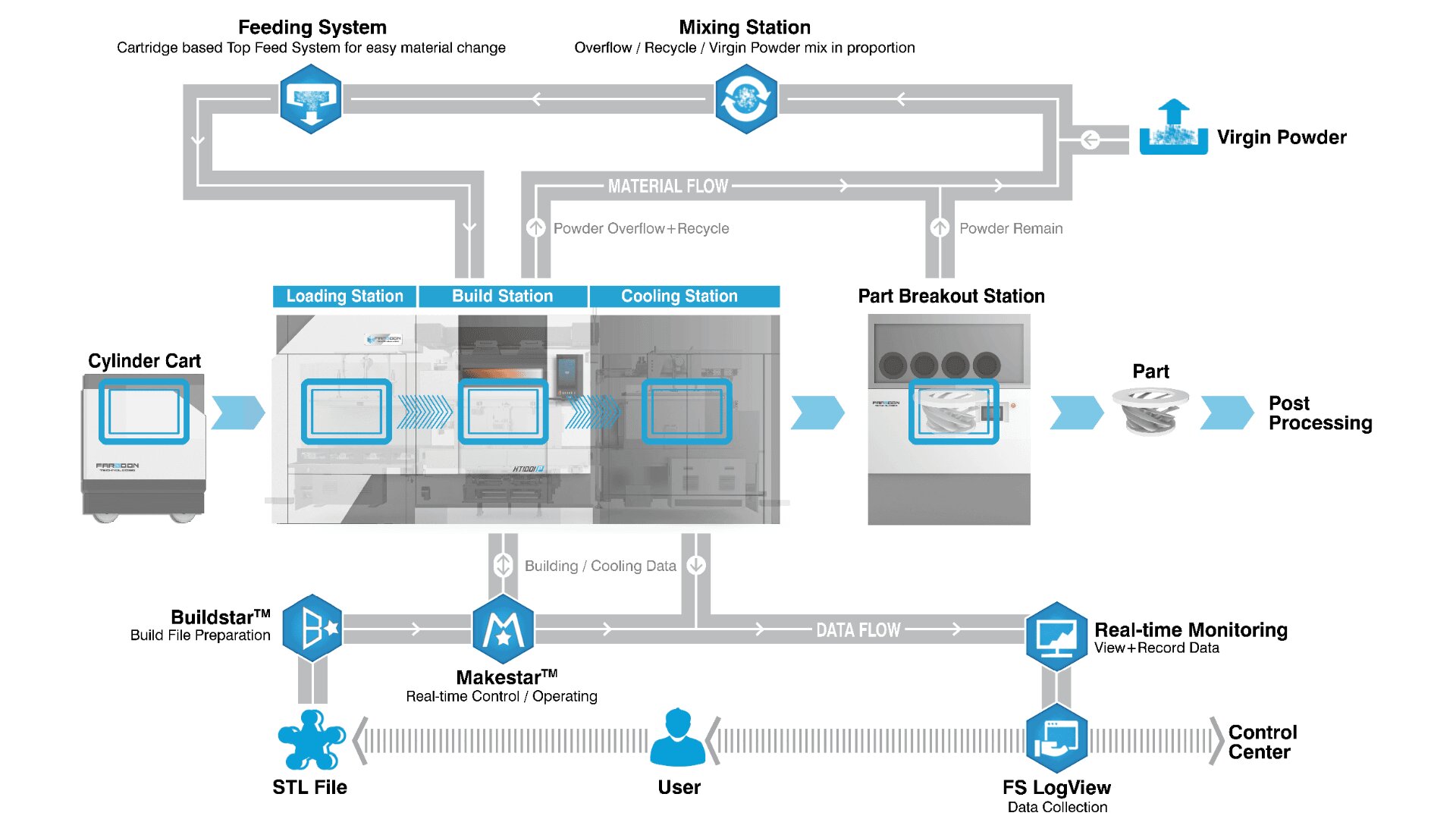

The CAMS systems are designed from ground up with manufacturing in mind. Equipped with an integrated conveyor system for build cartridge transportation between loading, building and cooling stations, the CAMS systems allow for maximized production turnover with minimal machine down time between the build cycles. Once the first build is completed, the build cartridge will be conveyed to cooling station for heat-removal under an inert atmosphere without taking up value machine build-time; meanwhile the user is able to load the second build cartridge to start the next build thanks to the exchangeable cartridge strategy.

Enhances capabilities

The CAMS offers production capabilities for its users beyond the current state of the art. The medium to large build envelopes with multi-laser configurations allow for accelerated fabrication of larger parts or large quantities of parts at a reduced cost. The polymer CAMS systems are capable of a greater temperature range than current laser sintering systems with build chamber temperature reaching 220℃ allowing for processing of high-performance materials.

Automated workflows

The CAMS metal and plastic systems are designed with comprehensive, highly efficient top-feed powder delivery system offers ease of integration into industrial-scale powder management infrastructures for production of quality, repeatable parts. The closed-loop powder system with increased automation enables minimal contact with the powder operation.

By April 2024, Farsoon is proud to offer total of 4 platforms in CAMS family – HT1001P, Flight HT1001P in the CAMS plastic section; FS422M and the latest FS721M-CAMS in the metal section.

HT1001P Platform

As the first entry of CAMS technology, Farsoon announced during Formnext 2017 the development of CAMS HT1001P Dual laser system – the first plastic laser sintering platform integrating CAMS concept. As of today, the HT1001P still stand as the largest plastic powder bed fusion system on the market with a 1000 x 500 x 500mm build volume as well as being able to achieve build chamber temperature of up to 220℃ allowing for the production of high-performance parts in automotive, aerospace and industrial manufacturing.

Flight HT1001P Platform

The innovative application of high-speed FLIGHT® (Fiber laser) Technology on HT1001P CAMS platform boosts industry-leading productivity for large-sized parts. Featuring expanded build cylinder measuring 1000mm×500mm×450mm and up to quad 300-watt fiber lasers, the Flight® HT1001P creates ultra-fine laser spots with fast scanning speed of up to 20m/s (66ft/s) for each; the continuous batch production capability significantly improves machine uptime and offers up to 10 times throughput yield per floor area compared to standard 400mm-size laser sintering system within the same time frame.

FS422M Platform

The FS422M is the new generation medium-large scale metal laser PBF system offering continuous production capability with up to quad lasers configuration. With expanded build size 425 x 425 x 550mm and highly efficient multi-laser scanning strategy, the FS422M offers optimal volume build rate up to 150cm3/h for significantly improved throughput for industrial scale series production.

FS721M-CAMS Platform

Since first introduced during TCT Asia 2021, the FS721M large-format metal platform has been well adopted by industrial customers in automotive, molds & tooling fields and large-format part fabrication. Addressing the needs to further enhance the production yield and manufacturing turnover, in March 2024 Farsoon integrates CAMS Concept with the eight 500W or 1000W lasers for FS721M platform featuring an expanded rectangular build cylinder of 720 x 420 x 390 mm; opening up many new potentials for high-volume productivity, increased automation and reduced operational cost.

Looking forward the future models of production such as Industry 4.0 the CAMS Concept is to offer continuous AM factory-scale production for high quality medium to large sized end-use components for a significant lower price per part. European customers are welcome to join us later from May 14th to 16th at Rapid. Tech 3D 2024 Booth 2-305 in Erfurt, Germany, or contact wehelpyou@farsoon-eu.com for more information.

About FARSOON

FARSOON Technologies, founded in 2009, is a system supplier of industrial grade plastic laser sintering and metal laser melting systems. Farsoon has developed a team of world-class experts with competencies in electrical/mechanical engineering, laser, scanning and optics, thermal controls, as well as material development and applications engineering. As a globally diverse company, Farsoon was founded with the clear vision and core commitment to creating open platform systems which will give the industry the freedom to innovate and expand the implementation of additive manufacturing in the global product’s marketplace.

Learning from the market about customer needs, Farsoon has moved to address the need for higher levels of productivity, improved feature details, and enhanced operational efficiency and flexibility. Farsoon’s latest innovations like the Continuous Additive Manufacturing Solutions (CAMS) and the very accurate and ultra-fast Flight® Technology stand for highest production rates and real industrial use of Additive Manufacturing.

Farsoon´s subsidiary FARSOON Europe GmbH (Stuttgart, Germany) provides the whole range of machine portfolio as well as local service and technical support activities.