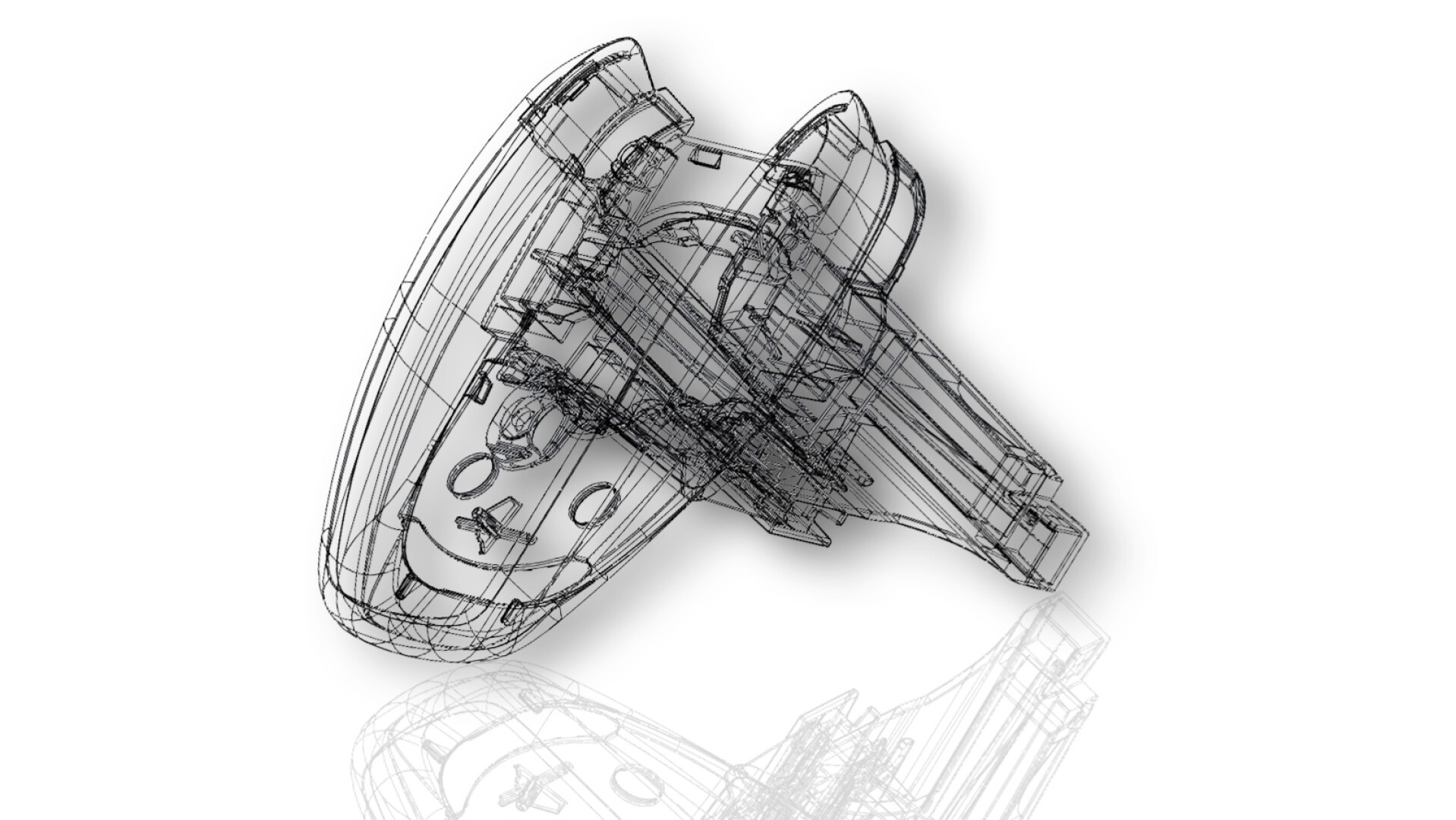

Product development with 3D scanning technology

We use modern 3D scanning and measuring technology for precise recording, measurement and reproduction - ideal for unique items, spare parts or models without digital data. All measurement data is documented according to customer specifications and archived in a traceable manner.

We use modern 3D scanning and measuring technology to generate geometry data in-process and to capture models provided to us for further processing. Our products and castings are manufactured and measured according to the customer’s specified tolerances and dimensional requirements, with the data stored in a structured manner for future traceability.

In addition, we use a 3D scanning system for measurement tasks as well as for unique parts, components without digital data, or for reproducing (replacement) parts of older systems. A 3D measuring arm – a combination of tactile and non-contact sensors – is used for this purpose.