Use the robot like a machine tool

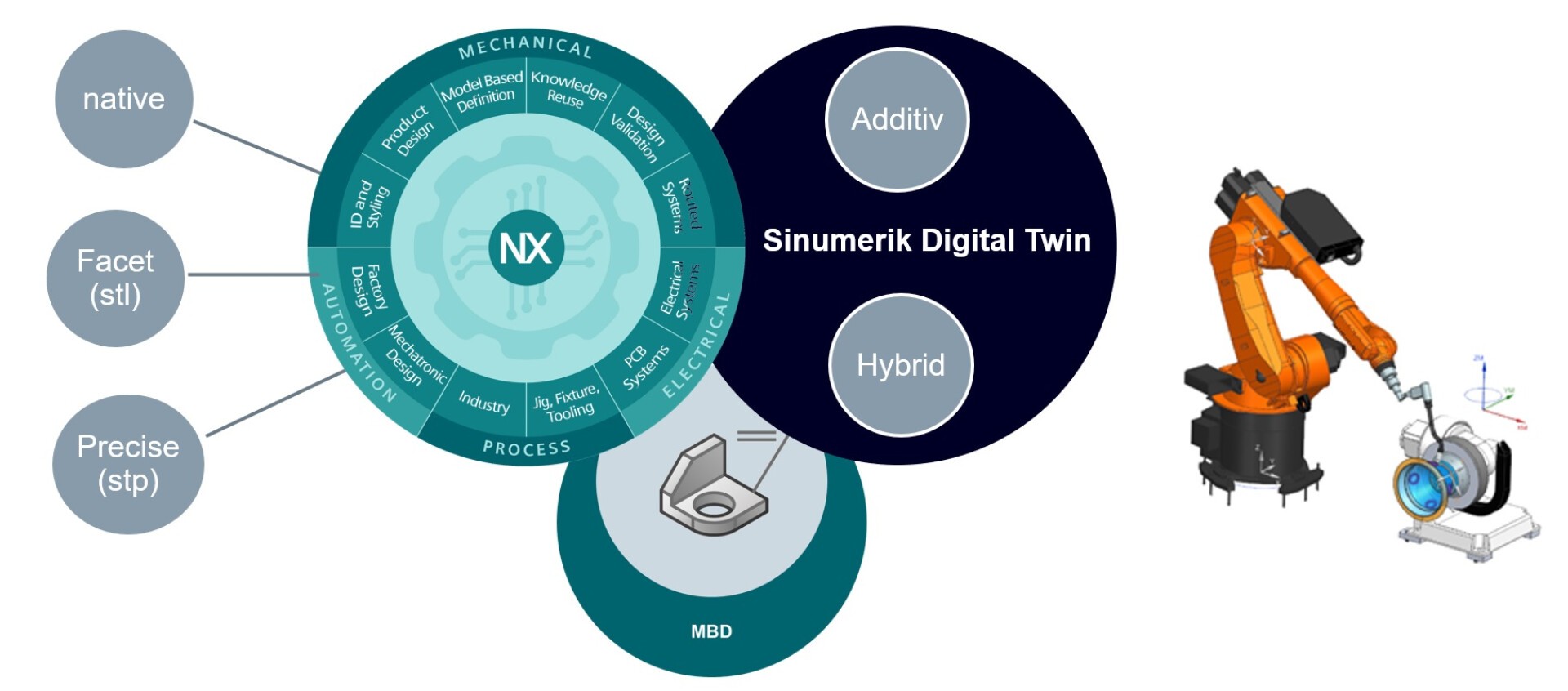

Benefit from the holistic approach of path planning, time prediction and simulation for hybrid manufacturing with Siemens NX and Sinumerik Digital Twin.

As a long-standing Siemens software partner, ARC Solutions GmbH provides digital planning and simulation solutions for machine tools, industrial robots and special kinematics.

The latest offering is the Sinumerik Machine Tool Robot (MTR) designed for direct machining. MTR is characterised by high path accuracy and significantly higher dynamic rigidity. The Sinumerik MTR is based on an intelligent control concept that gives industrial robots the characteristics of machine tools.

This enables high-precision path applications, even when machining hard and tough materials such as steel, whose material toughness increases the cutting forces and requires more damping. Compared to conventional industrial robots, Sinumerik MTR offers a 200 to 300 per cent increase in path accuracy and significantly higher dynamic rigidity to meet these challenges.

These features make Sinumerik MTR ideal for industries such as aerospace and defence, automotive and many other high-precision robot applications, including post-processing of 3D printed metal parts. In addition to improved accuracy, the new control concept brings with it an increase in productivity of 20 to 40 per cent. This also makes the Sinumerik MTR extremely attractive for applications with lower process forces, such as additive manufacturing.

With the ‘Digital Native CNC’ Sinumerik One, the digital twin and bidirectional integration in Siemens NX, ARC Solutions offers a key element for the digital transformation of discrete manufacturing processes using virtual simulation, forecasting and testing.