3D printing in mechanical engineering: making targeted use of potential

Increasing competitive pressure demands new solutions. Additive manufacturing opens up real added value in mechanical engineering - from function-optimized components to fast metal prototypes without toolmaking. Discover real practical examples.

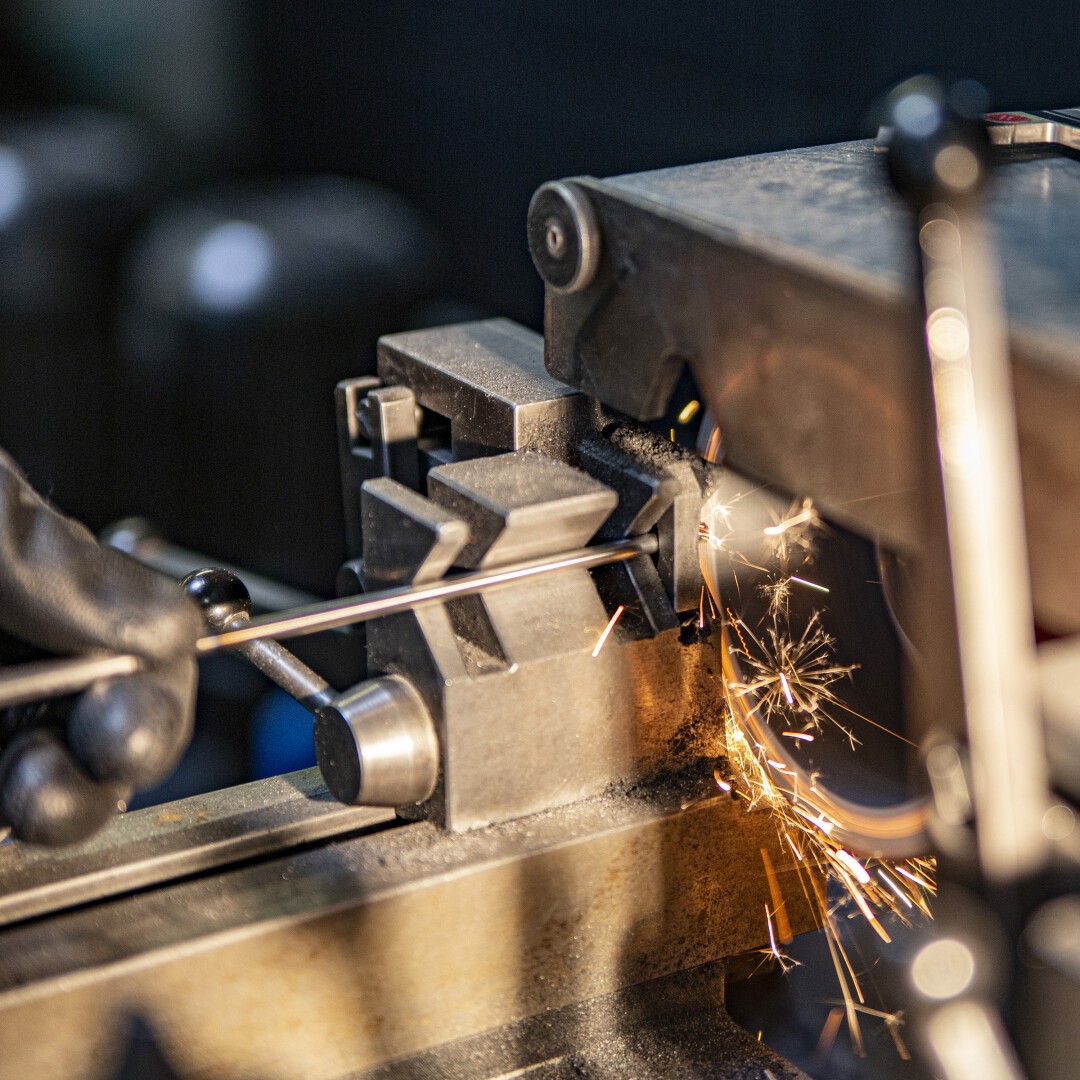

Plasser & Theurer urgently needed large cast parts for testing a new tamping unit. Traditional casting wasn’t an option due to time and cost. FIT delivered five fully functional WAAM prototypes (total weight: 500 kg) within weeks—on time, high quality, and test-approved.

Mover as part of a magnetic transport system

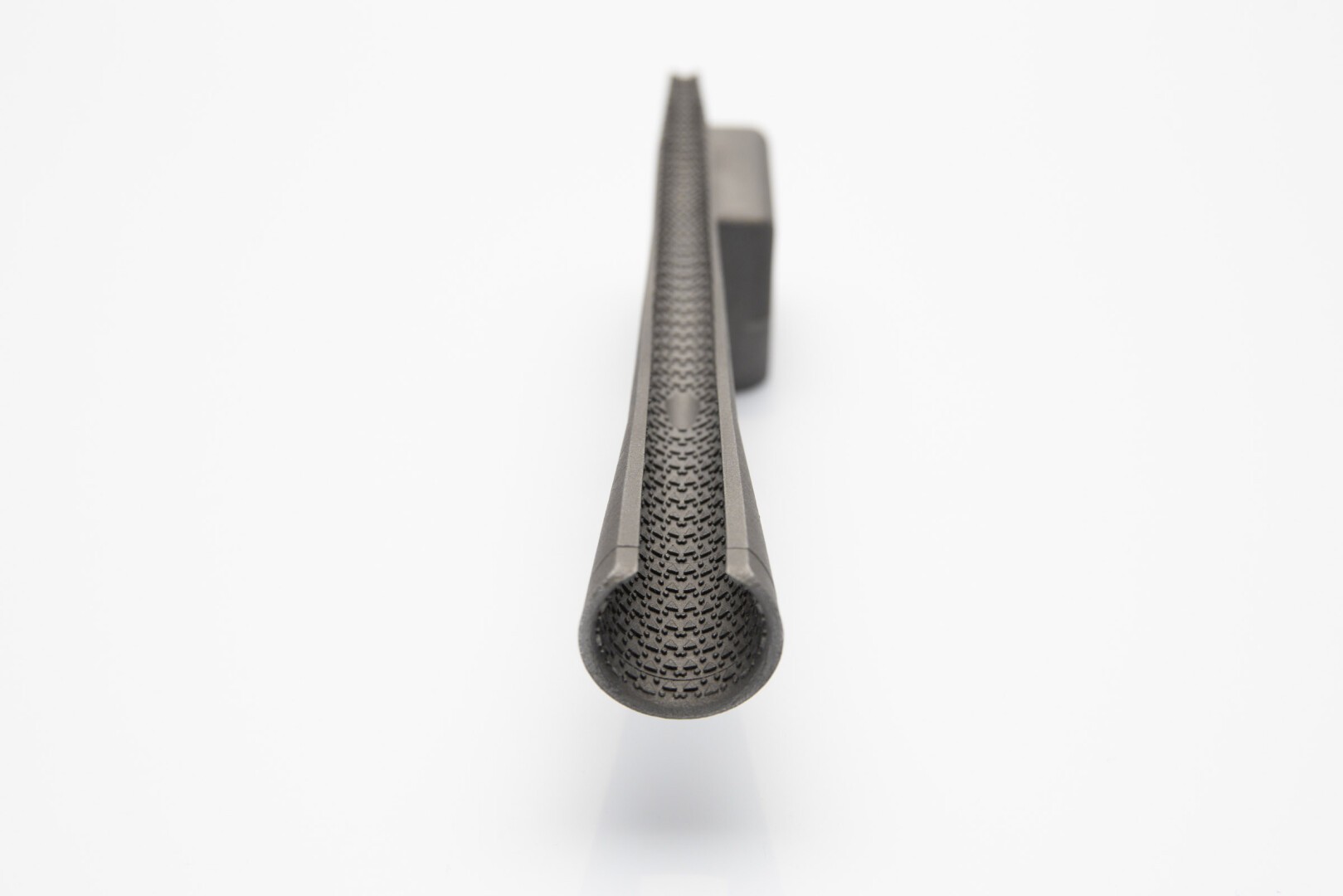

Garniture tongue for cigarette production

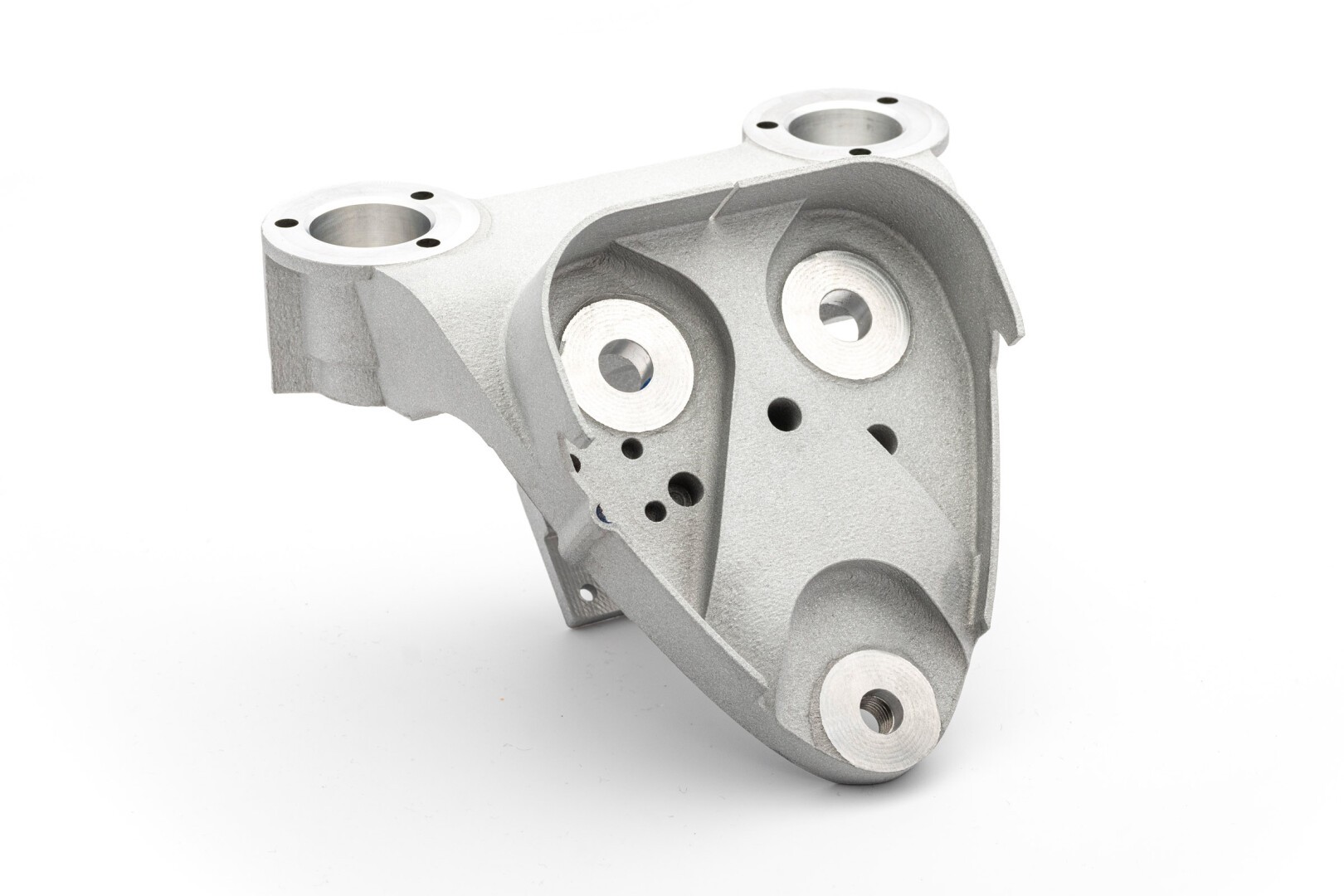

Swivel bearing for track construction

Mover as part of a magnetic transport system

To boost productivity, Bosch aimed to speed up its magnetic transport system by reducing the weight of its movers by 30%. FIT redesigned the component as a one-piece, additively manufactured lightweight version—enabling faster cycle times and higher output. More in our upcoming Inspiration Book!

Garniture tongue for cigarette production

In filter cigarette production, the infeed finger is key to keeping machines running. Hauni optimized this part with complex internal structures—only possible through additive manufacturing. Produced by FIT, the solution ensures smooth operation and prevents downtime.

Swivel bearing for track construction

When large cast parts were urgently needed for a new tamping unit, additive manufacturing provided the answer. FIT produced five test-ready WAAM components (500 kg total) within weeks. Delivered on time, the high-quality parts ensured a successful test run.