Complex Geometries in short lead times by 3D-model driven investment casting

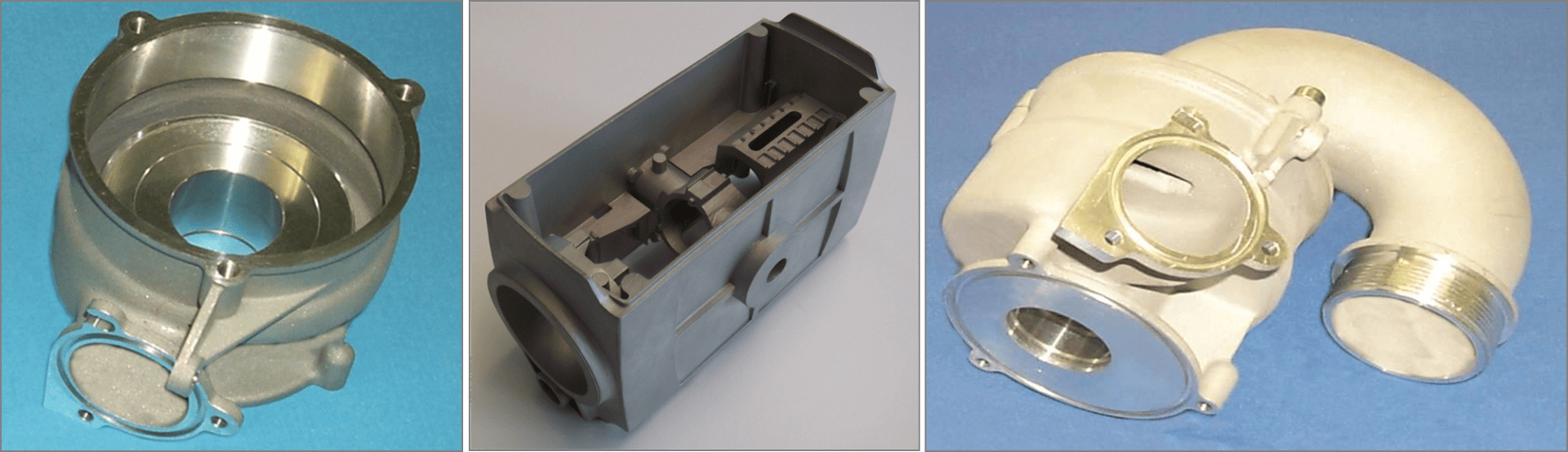

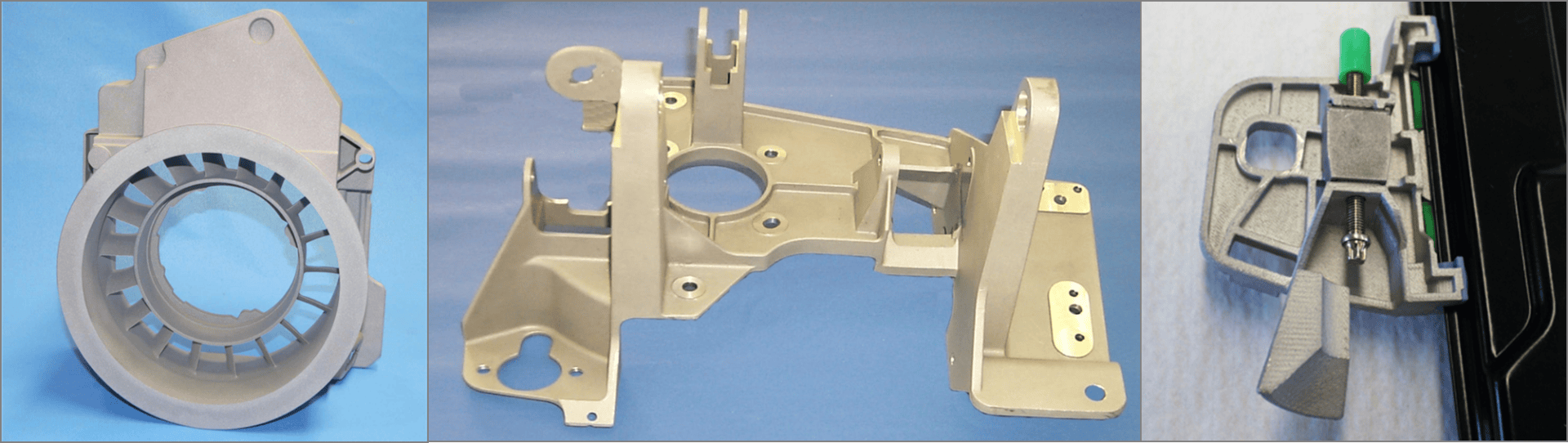

With assistance of 3d-printed models, investment casting helps to produce variety of heat sinks in small quantities and short production times, even by as heat sinks.

Heat sinks must dissipate as much heat as possible from electrical components or light sources. This is achieved, among other things, by a particularly large surface area (variety of cooling fins) and a high coefficient of thermal conductivity on the material side. Manufacturing processes that meet these requirements for small quantities are limited. 3D printed metal parts are suitable for prototypes, but reach its limits where closely spaced cooling fins are oriented along all geometric axes.

For optimization processes or small series, investment casting using the plaster flask is suitable for these geometries. When using 3D-printed lost pattern, this process is completely free of demoulding constraints and can be realized in a short time thanks to the fast mould making of a plaster mould. The usually different x-y-z scaling values are partly determined experimentally using an initial metal casting prototype - the fast investment casting process makes this possible.