ZF Group 𝗗𝗲𝗺𝗼𝗰𝗿𝗮𝘁𝗶𝘇𝗲𝘀 𝗔𝗱𝗱𝗶𝘁𝗶𝘃𝗲 𝗠𝗮𝗻𝘂𝗳𝗮𝗰𝘁𝘂𝗿𝗶𝗻𝗴 𝘄𝗶𝘁𝗵 𝟯𝗗 𝗦𝗽𝗮𝗿𝗸!

🕒 𝟱𝟬% faster Part Request to Production Process | 📈 𝟮𝟱%+ increased Accuracy! Interested in knowing more? Check out the full case study based on a real world example, on how ZF achieved these numbers using 3D Spark!

3D Spark GmbH

Hamburg,

Germany

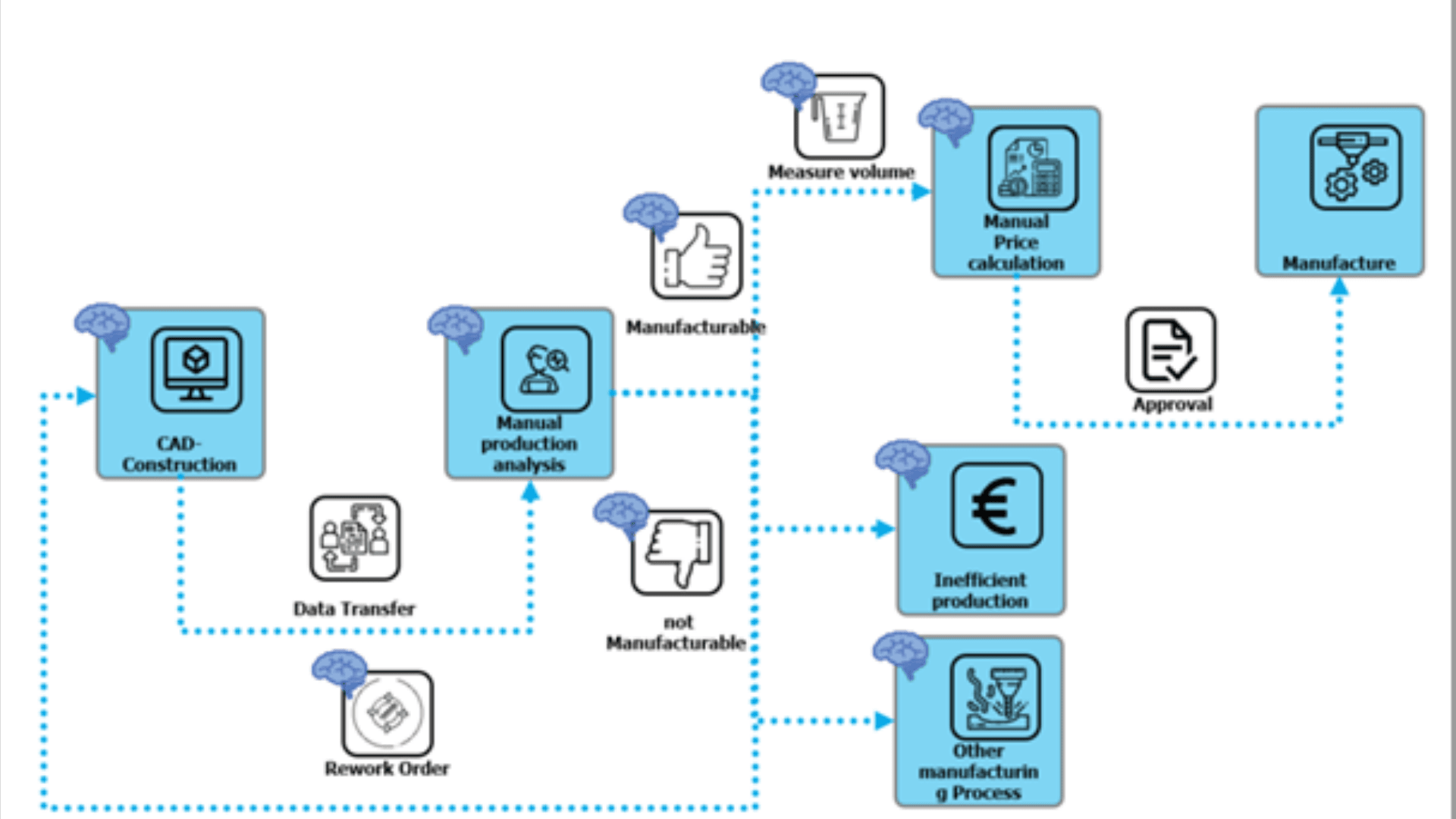

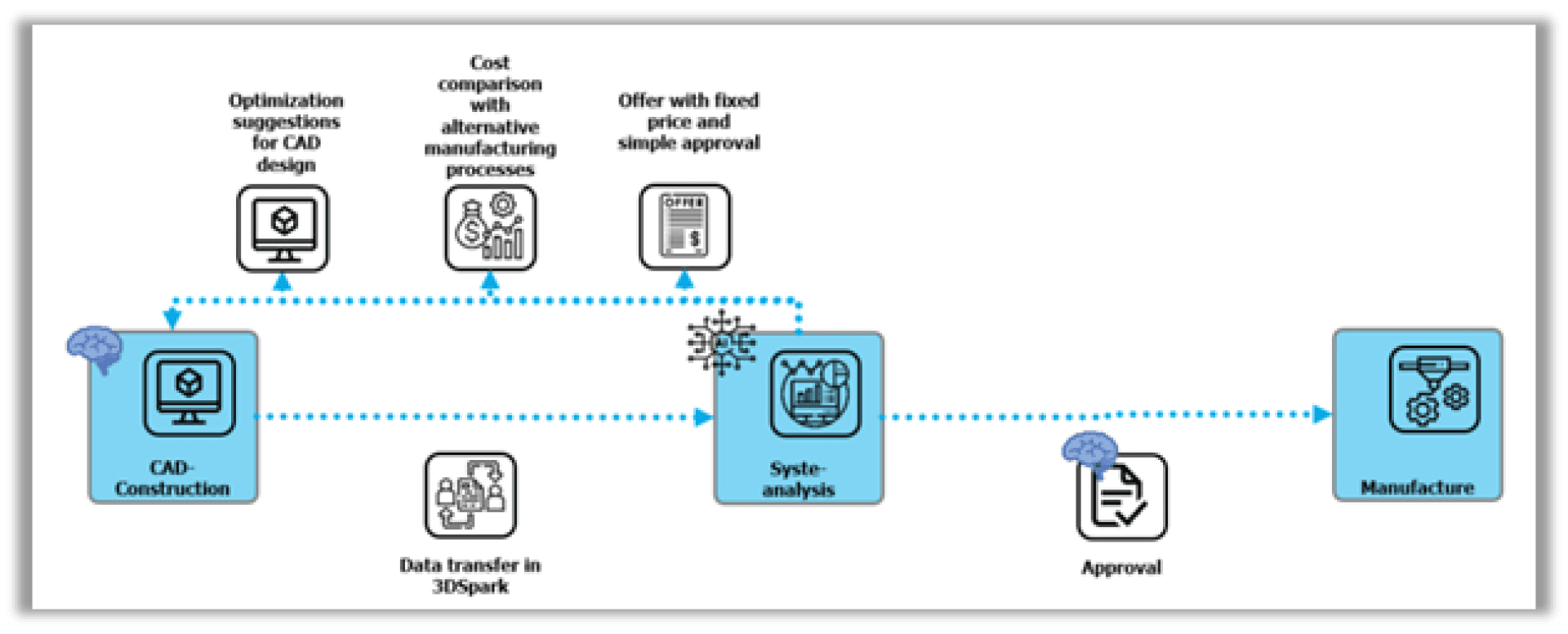

𝗛𝗼𝘄?

- Old part request to production process: Time-consuming processes, heavy reliance on manual expertise.

- New part request to production process: Streamlined operations, automated analyses, and reduced error potential.

𝗪𝗵𝘆 𝗜𝘁 𝗠𝗮𝘁𝘁𝗲𝗿𝘀:

- Cutting feasibility and costing time by 50% speeds up the whole process from part request to production, making it more efficient.#

- Boosted manufacturing accuracy by over 25%, making outcomes more reliable and precise.

- Democratized access to advanced manufacturing tools, empowering both experts and novices alike.

𝗥𝗲𝗮𝗹-𝗪𝗼𝗿𝗹𝗱 𝗜𝗺𝗽𝗮𝗰𝘁:

The transformation of the 𝘃𝗮𝗹𝘃𝗲 𝗯𝗹𝗼𝗰𝗸 𝗽𝗿𝗼𝗱𝘂𝗰𝘁𝗶𝗼𝗻 𝗽𝗿𝗼𝗰𝗲𝘀𝘀 serves as a stellar example. This not only showcases the practical benefits of the collaboration but also highlights how real-world applications are being revolutionized.

Explore the full case study here: - Case Study