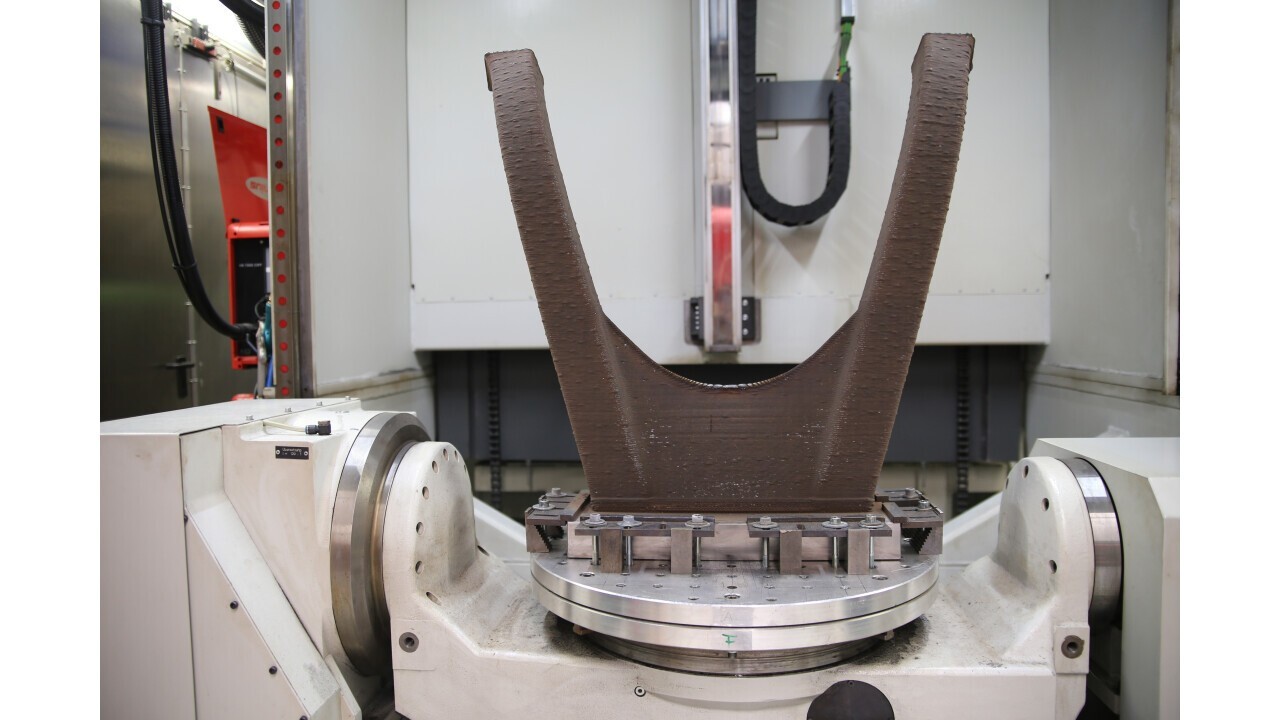

Application example: Auxiliary arm for bridge-laying tanks

Krauss-Maffei Wegmann builds the Boxer bridge layer for military applications. The aim of a pilot project with FIT AG was to realize weight savings based on the structural component of an auxiliary arm, an element of the laying device.

Krauss-Maffei Wegmann builds the Boxer bridge layer for military applications. Bridge-laying tanks are used to bridge obstacles in the terrain, such as small rivers or ravines, and must be able to safely carry heavy vehicles. They are also used as mobile temporary bridges for bridges washed away by flooding, as was the case during the flood disaster in the Ahr Valley. The pilot project with FIT sought to identify opportunities for weight reduction and manufacturing cost savings based on the structural component of the auxiliary arm, an element of the laying device. Using the contour-following welding process Wire Arc Additive Manufacturing (WAAM), a near-net-shape blank was produced in just two days of production time that meets the technical specifications and achieves a weight reduction of almost 20% (17.65%). This means that the prototype created can be very well conceived as a casting substitute.