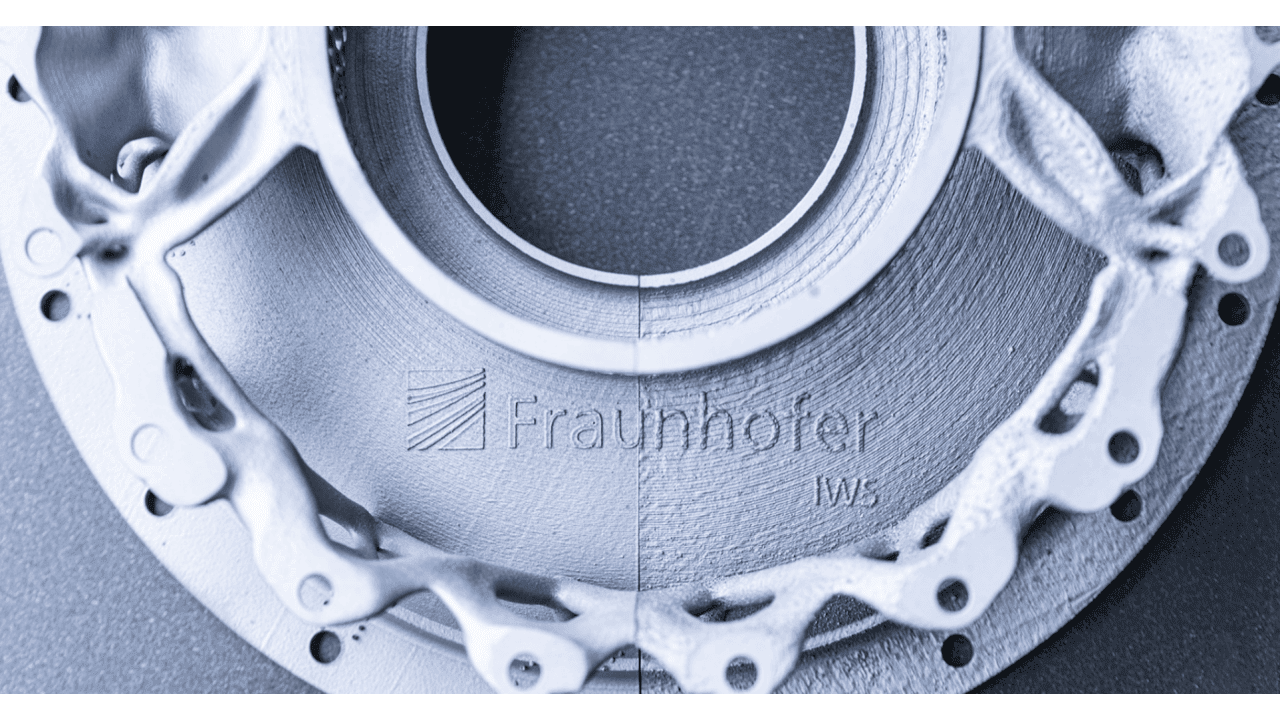

FAST - Prototype development for the future of aviation

Methodical approach to process chain analysis and shortening, Design 4 AM, Fast powder characterization

The aviation industry faces intense innovation pressure and rapidly evolving requirements. Rapid development of functional prototypes is essential to maintain adaptability and competitiveness. Currently, prototype development often takes several months from initial design to testing. The goal of the LuFo project FAST is to reduce this timeframe to just six weeks - from powder characterization, design for additive manufacturing (DfAM), additive manufacturing and post-processing to component geometry validation.

Key elements include a continuous digital process chain, early Failure Mode and Effects Analysis (PFMEA), optimized process parameters, and targeted digitally supported pro-cess analysis. Clearly defined interfaces and standardized process flow diagrams ensure efficient collaboration throughout the process chain. Simulations and new approaches to function integration further increase the speed and quality of prototype development.

The Fraunhofer IWS contributes its expertise in metal 3D printing and enables the accelerated realization of innovative components through comprehensive powder characterization, material studies and simulation-based process optimization. The overall goal is to establish additive manufacturing as a key enabler for fast, flexible and sustainable aerospace development.

Presentation language: GER

Speakers (1)