3D printing in miniature – high-precision additive manufacturing in the micro range

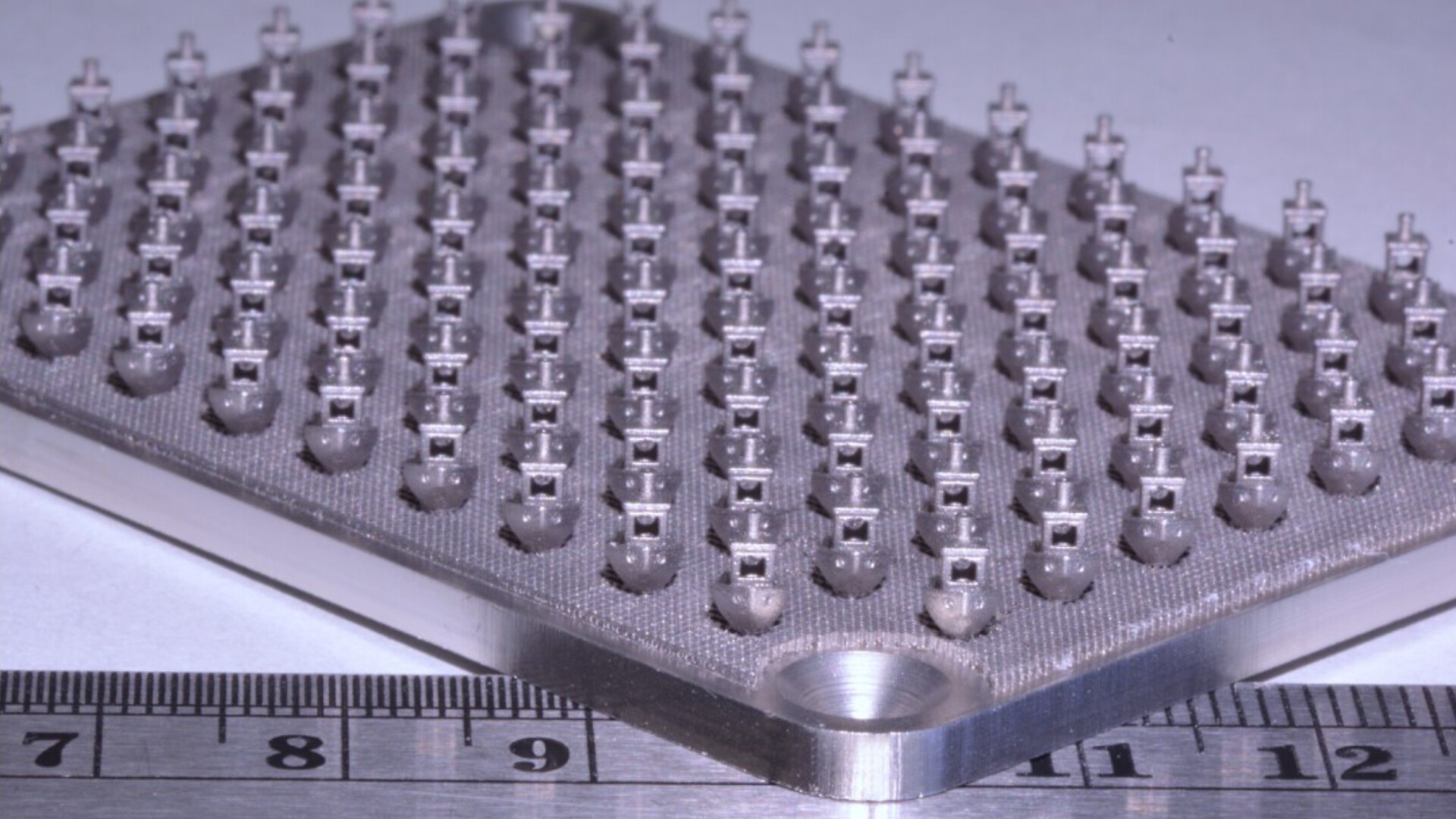

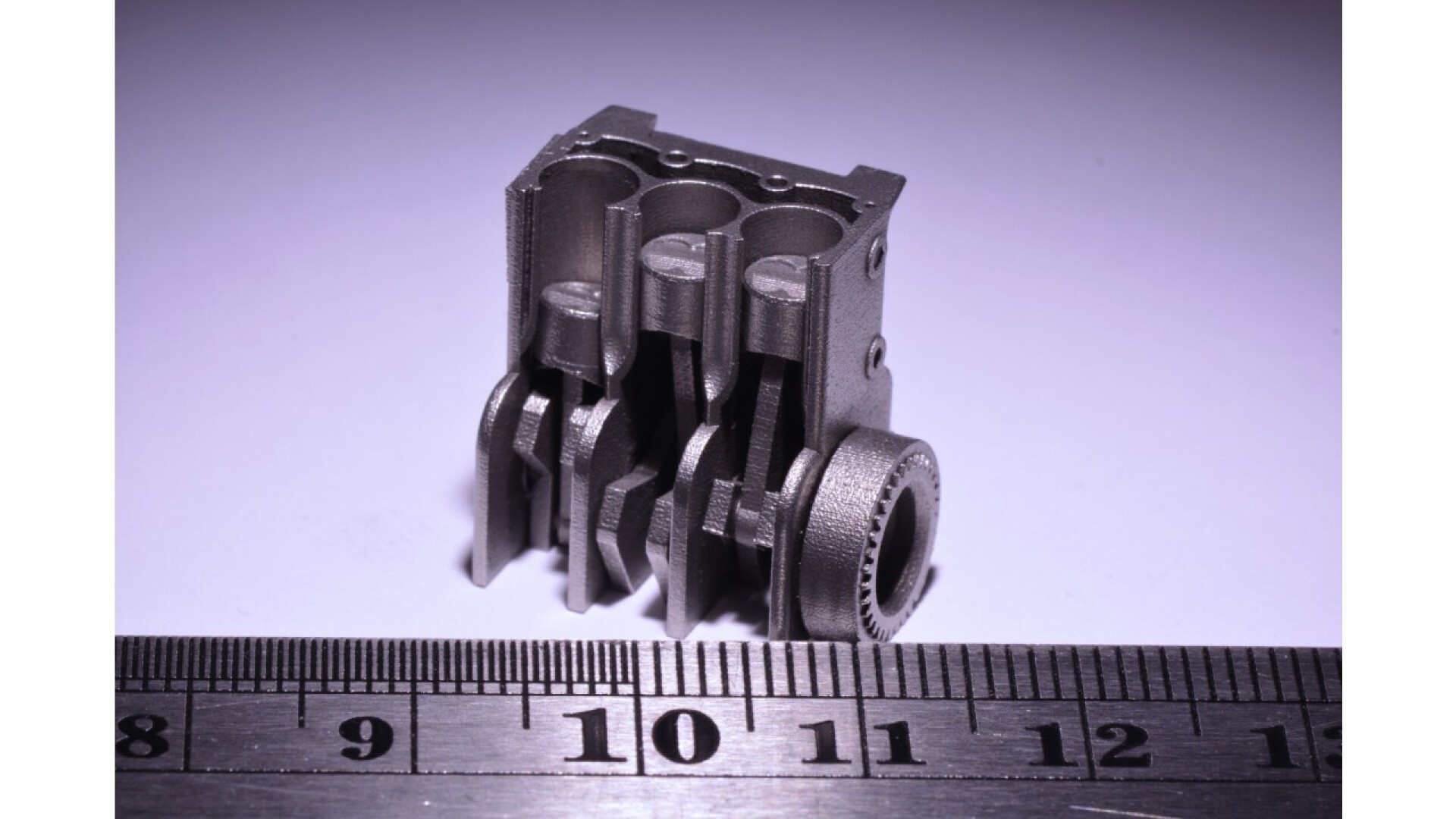

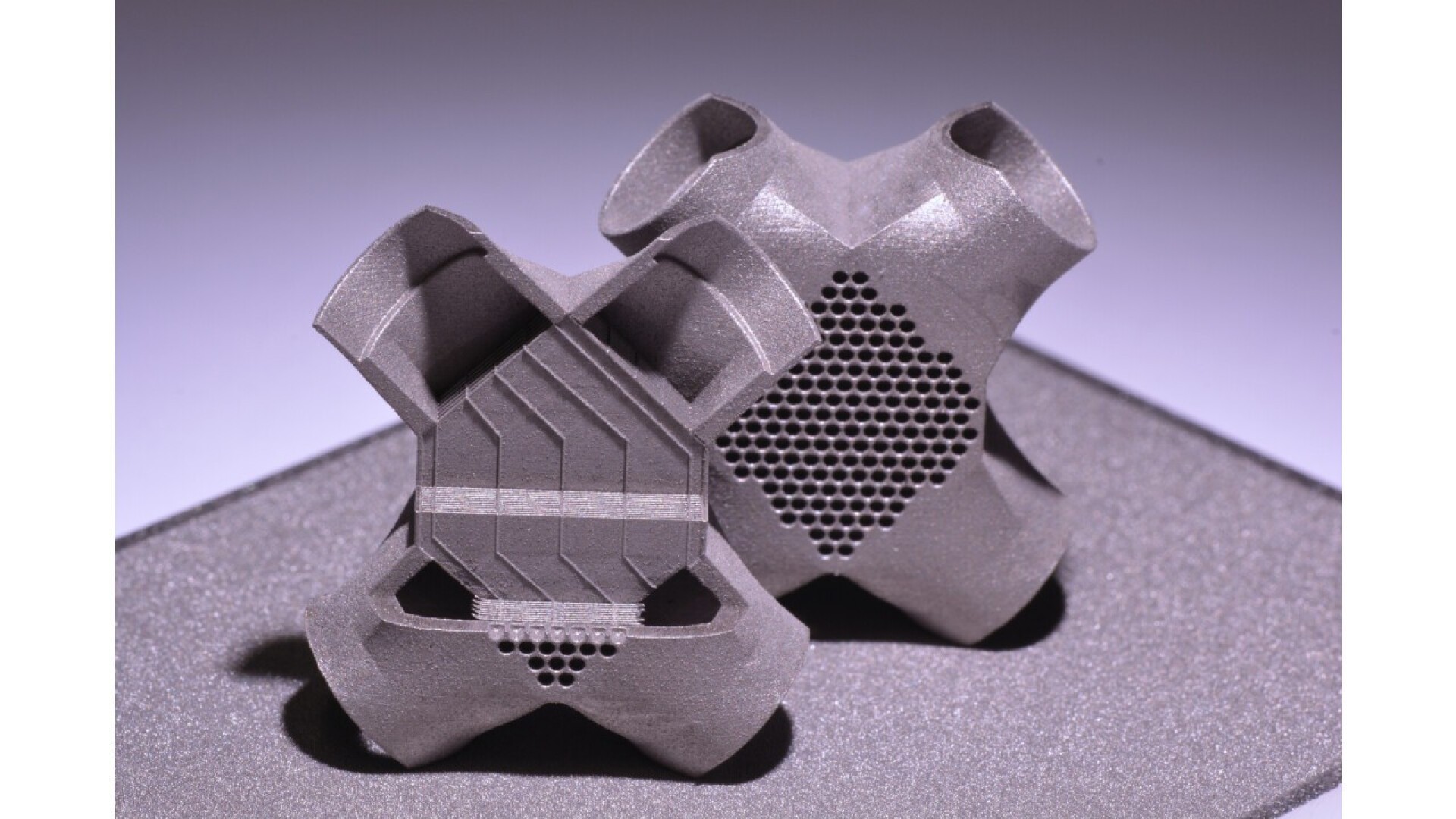

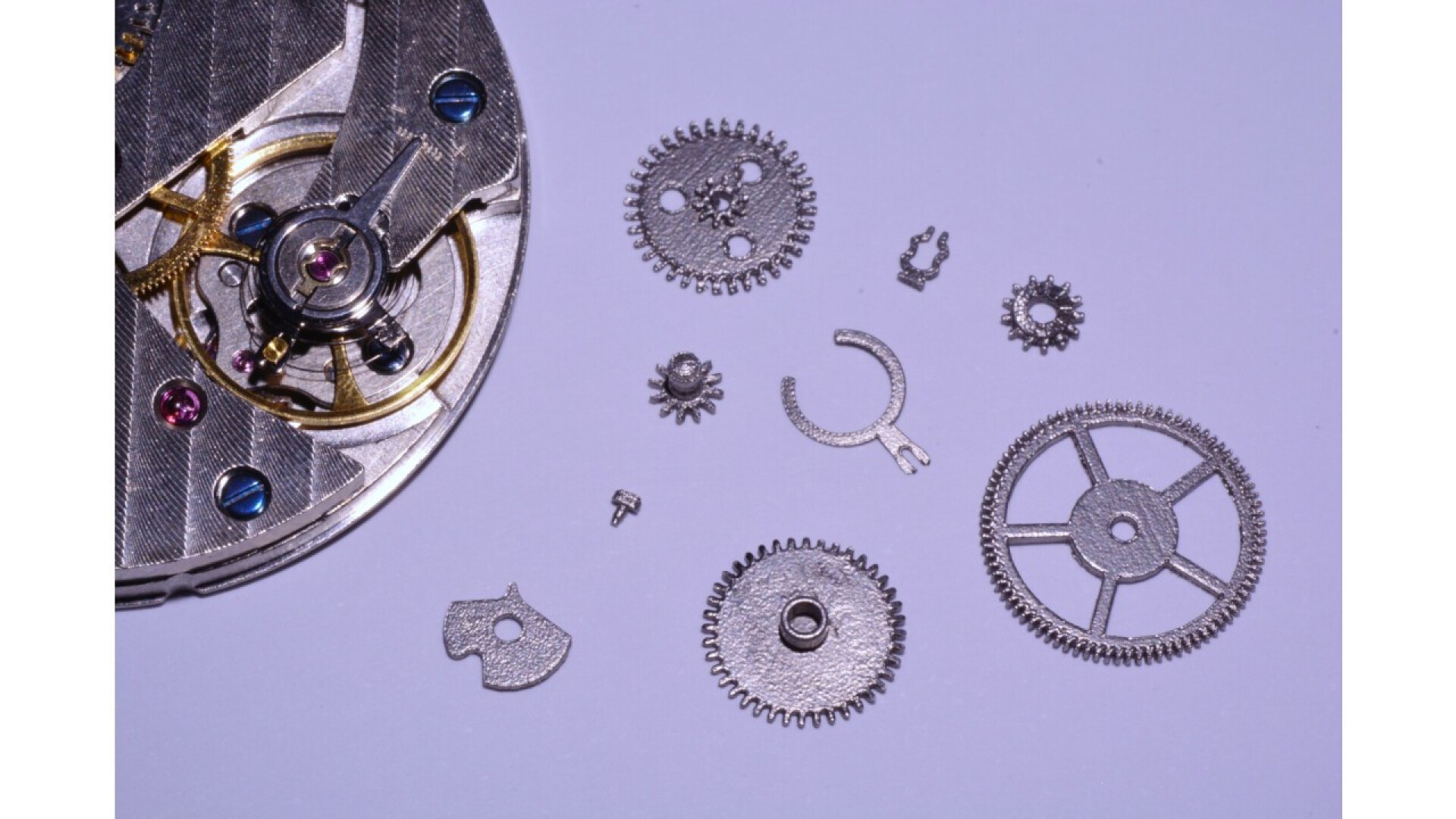

The Micro-SLM process enables the production of metallic or ceramic components with high structural resolution and very low surface roughness. For example, complex internal structures and movable features in the range of a few micrometers can be realized.

The Micro-SLM process developed at the Laserinstitut Hochschule Mittweida (LHM) is a further development of the established laser powder bed-based 3D printing of metal components (also known as SLM or L-PBF) in the micro range. It enables the 3D printing of components with higher structural resolution, lower surface roughness and higher dimensional accuracy using very fine powders with grain sizes of less than 10 µm and a laser spot of approx. 30 µm. This makes it possible to produce precision components with structural resolutions of up to 30 µm and layer thicknesses of up to 5 µm. Compared to the conventional SLM process, this means an improvement in resolution by a factor of 4 - 5. The surface roughness of the untreated components is already only Ra = 2.5 µm. Subsequent glass bead blasting can reduce the roughness to Ra = 1.0 µm and dry electropolishing can even reduce it to Ra = 0.1 µm.