3D printing in the food industry

3D printing is fundamentally changing the food industry: whether customized foods, innovative designs or sustainable ingredients – the technology opens up new ways to produce creative, healthy and environmentally friendly foods.

Once limited to the manufacturing industry, 3D printing has now also taken over the food industry and promises to fundamentally change the way we look at food. Combining cutting-edge 3D printing technologies with food production opens up an exciting dimension of culinary possibilities and turns conventional notions of food production on their head. At the heart of this fusion of technology and culinary arts is the idea that 3D printing not only offers a more efficient production method, but also a space for unparalleled creativity. Applications range from customizing food to creating unique textures and shapes that go far beyond what traditional production processes allow. This era of 3D printing in food promises not only culinary innovation, but also a paradigm shift in the approach to food. Welcome to a new era of gastronomy where the boundaries of what is possible are constantly being redefined and 3D printing as a creative tool takes the art of cooking to a whole new level. At rapid.tech 3D you can exchange ideas with exhibitors in this field and experience 3D printing of food live.

Filaments in food 3D printing: Biocompatible polymers and protein sources in focus

Filaments for food 3D printing play a crucial role in the evolution of this innovative technology. Unlike conventional 3D printing processes that predominantly use plastics or metals, food 3D printing requires food-grade filaments that are not only printable but also safe and compatible for human consumption.

Biocompatible polymers occupy an important position in the context of 3D printing in the food industry. A promising example is pectin, a naturally occurring polymer found in many fruits such as apples and citrus fruits. Pectin not only offers good printability but also has gelling properties, which enables the production of textured foods. This biocompatible polymer has the potential to serve not only as a carrier material but also as a texturizing substance for 3D printed foods. Pectin is suitable for fruit jellies and slices in the field of food 3D printing.

Another interesting biocompatible polymer is agar-agar, which is derived from algae. Agar-agar forms a gel-like substance that is solid at room temperature and liquefies when heated. This makes it ideal for creating gel structures in printed foods. These include, for example, 3D printed seaweed snacks or seaweed-based side dishes, where the printing technology takes care of the shaping and structuring. Using agar-agar as a material in 3D printing foods not only allows unique textures to be created, but also opens up possibilities for precisely controlling release profiles of flavors and nutrients.

In addition to biocompatible polymers, work is also being done on the integration of protein-based food-grade filaments. The focus of protein-based filaments is primarily on the use of plant proteins. These proteins, obtained from sources such as peas, soy or legumes, can represent a sustainable alternative to animal proteins. This could include the production of vegetarian meat substitutes or textured plant-based foods. In addition, research is also being carried out into insect proteins in the field of 3D-printed foods, which are considered a promising resource due to their low ecological footprint.

The future of food: Various foods from the 3D printer presented

3D printing is revolutionizing food production and enables the reproduction of meat, chocolate, fish, sweets and much more. This innovative technology not only offers sustainable food options, but also opens doors to a personalized world of enjoyment. It is important that the printed filaments are food-safe. Immerse yourself in the fascinating world of 3D printing at Rapid.Tech 3D, where culinary delights and environmental awareness merge in an innovative way.

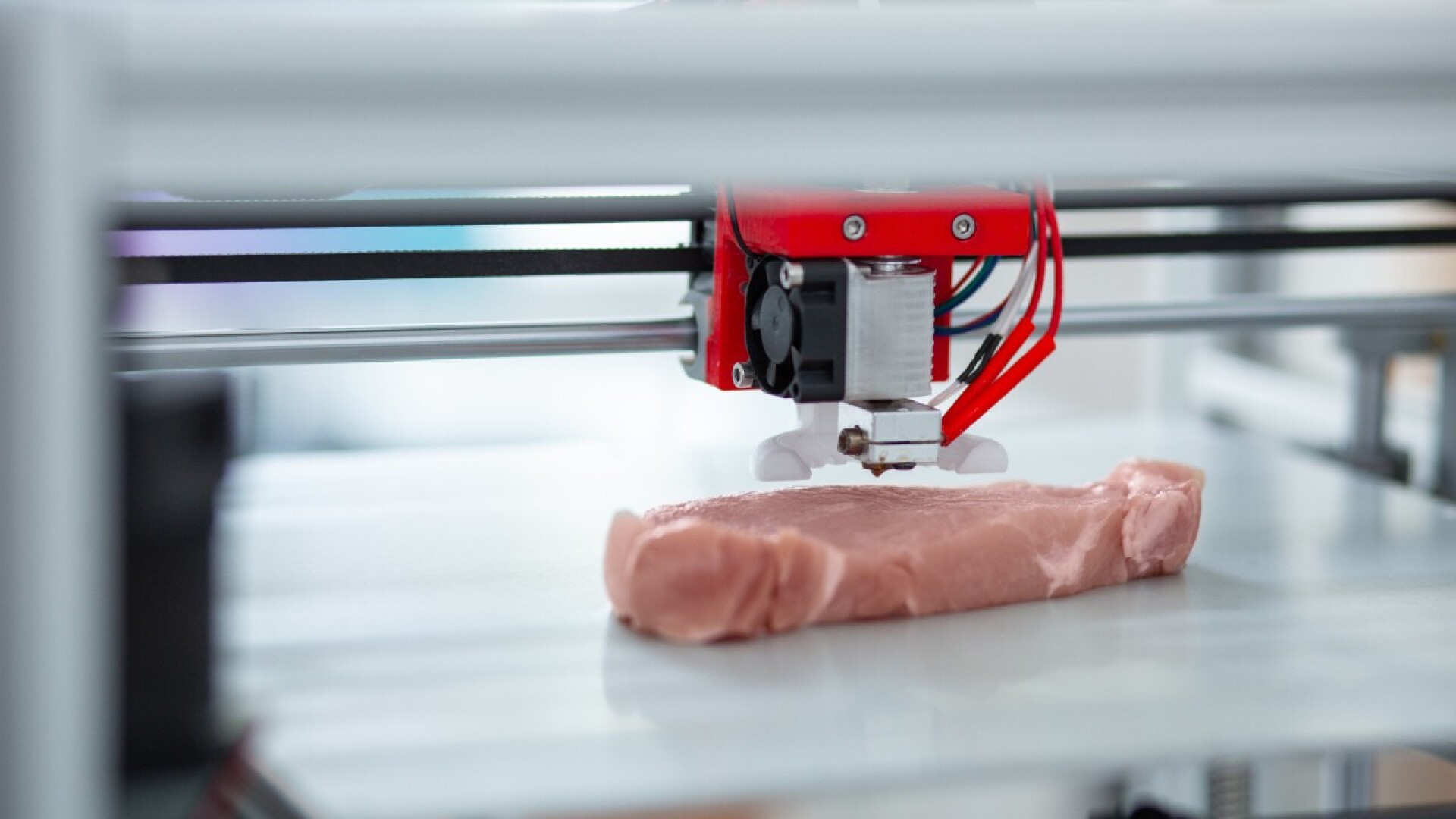

Meat from the 3D printer

3D printing meat represents a fascinating advancement in food technology by offering the possibility of creating tasty meat alternatives based on plant-based proteins. By precisely layering and shaping these proteins in 3D printing meat, food-grade products are created that not only mimic the visual and flavor qualities of real meat, but also represent a more sustainable dietary option.

This innovative approach to meat production offers numerous advantages, including reducing the ecological footprint compared to conventional meat production. Food-grade 3D printing of meat allows for targeted control over ingredients, allowing fat and cholesterol levels to be regulated. This technology helps meet the growing demand for sustainable dietary options and could provide an answer to the challenges of global food production. The adaptability of food-grade 3D printing of meat also opens up space for creative innovation in the culinary world. From individual textures to novel flavor combinations, 3D printing of meat enables a variety that overcomes the limitations of traditional meat production. Whether for vegans, flexitarians or the environmentally conscious, 3D printing of meat presents a promising future in which enjoyment and sustainability go hand in hand.

Chocolate from the 3D printer

This innovative process uses melted chocolate as a filament to create artistic, custom shapes and designs. 3D printing chocolate allows precise control over the design of chocolate products, from complex patterns to personalized lettering.

The use of biocompatible filaments ensures not only food safety but also the quality of the printed chocolate. This approach not only opens up new avenues for the creative presentation of chocolate creations, but also enables the development of unique textures and flavor profiles. From customized chocolate pralines to artistic chocolate sculptures, 3D printing chocolate offers an endless variety of possibilities. This marriage of tradition and technology not only creates visually stunning treats, but takes the enjoyment of chocolate to a new, personalized level. 3D printing chocolate is more than just a culinary innovation - it is a creative journey that appeals to the senses and redefines chocolate enjoyment.

Fish from the 3D printer

Food-grade 3D printing of fish uses special protein-based filaments, including plant-based proteins from peas, soy or legumes. These not only offer a sustainable option but also a good source of protein. Algae-based filaments are considered an environmentally friendly and nutrient-rich alternative for the authentic taste and texture of fish. More advanced approaches are working on cell-based materials, where fish tissue cells are cultured and integrated into 3D printing of fish. The choice of material is based on the desired properties of the fish product, including taste, texture and nutritional content.

This innovative method not only enables the creation of authentic-tasting fish alternatives, but also helps to relieve the burden on overfished stocks. 3D printing fish offers a personalized, resource-saving solution for nutrition-conscious consumers. Precise control over ingredients and texture creates fish alternatives that are not only tasty, but also nutritionally convincing. The technology of 3D printing fish could not only expand the variety of fish products, but also reduce the ecological footprint of food production. In a world where sustainable nutrition is gaining importance, 3D printing fish adds a sustainable dimension to the food industry and creates innovative solutions for the increasing demand for resource-saving alternatives.

Personalized sweets from the 3D printer

3D printing opens up an exciting dimension for those with a sweet tooth - the world of personalized candy. These 3D printed candies use biocompatible polymers such as pectin, agar-agar and alginate, which are derived from natural sources. Some technologies use sugar as a filament or enable the 3D printing of chocolate. Edible materials such as marzipan or fondant can also be 3D printed for personalized cake and pastry decorations.

The personalized production of sweets makes it possible to integrate creative shapes, patterns and even personal messages directly into the treats. Whether it is birthday parties, weddings or special occasions - 3D printing of sweets allows you to create sweet treats that are not only impressive in terms of taste but also aesthetically.

From geometric shapes to complex designs, the possibilities can be customized with 3D printing of sweets. The selection of ingredients and flavors also offers scope for creative taste experiments. This technology not only enables a unique culinary experience, but also the creation of sweets that delight not only the palate but also the eyes. 3D printing of personalized sweets takes snacking to a new level and turns sweet moments into unforgettable experiences.

Food safety in 3D printing: What you have to consider

Food safety in the context of 3D printing of food is a key aspect that plays a crucial role in the acceptance and integration of this innovative technology in the food industry. The pursuit of food safety means that the filaments used and the entire printing process are safe for consumption and harmless to health. Biocompatible polymers specifically developed for 3D printing of food are in focus to ensure this food safety. These polymers must not only have the required technical properties for the printing process, but also meet the highest standards in terms of food safety.

The selection of natural and edible raw materials plays a crucial role here to ensure that no harmful residues remain in the printed food. Another important consideration is the development of materials that are free of allergenic substances to ensure safety for a broad population. This means that when selecting biocompatible polymers, care is taken to ensure that they are free of potential allergens such as gluten or certain proteins. In addition to the choice of filaments, the printing parameters are also important. A precise and controlled printing process is crucial to ensure the quality and authenticity of the printed food. Regulatory institutions and certification bodies must be involved in the development process to establish guidelines and standards for food authenticity.

Food authenticity in 3D printing of food is not only a technical challenge, but also a commitment to the consumer community. To realize the full potential of 3D printing in the food industry, continuous collaboration between scientists, engineers and regulators is required to ensure that the printed food is not only innovative and creative, but also meets the highest safety standards. This is the only way to ensure that 3D printing of food has a sustainable and trusted future in our food world.

Benefits of food from the 3D printer

3D printed food offers a variety of benefits that can change the way we produce and consume food:

- Reduction of food waste: The precise printing process allows food to be produced in the quantities required. This helps reduce food waste by avoiding overproduction.

- Adaptation to special dietary needs: People with special dietary requirements, such as allergies or intolerances, can benefit from 3D printed food. The selection of ingredients can be adjusted accordingly to meet individual needs.

- Precise dosing of ingredients: 3D printing of food enables precise dosing of ingredients, which not only improves the accuracy of preparation, but also offers the possibility of specifically controlling specific amounts of nutrients.

- Efficiency in production: By using 3D printing in the food industry, complex structures and shapes can be produced more efficiently. This leads to an optimization of production processes and enables faster delivery of food.

- Creative design: 3D printing allows the creative design of food to an extent previously unimaginable. From artistic designs to unique textures, innovative and appealing products can be created that are not only tasty but also aesthetically pleasing.

- Diversity in diet: By allowing different textures and flavors to be combined in one food, 3D printing of food opens up new culinary dimensions and promotes diversity in diets.

- Rapid adaptation to trends: In the fast-moving world of food trends, 3D printing enables food creations to be quickly adapted to current preferences and trends. This helps to make product development more agile.

Challenges with food from the 3D printer

Even though food from 3D printers has many significant advantages, there are also some challenges that 3D printing of food (still) has to contend with:

- Regulatory hurdles: The legal and regulatory landscape for 3D-printed food is not yet fully developed. Clear standards and regulations need to be established to ensure the safety and quality of these foods.

- Cost factor: 3D printers for food are currently still relatively expensive. Costs need to fall to enable wider application and integration into the mass market.

- Consumer acceptance: Consumer acceptance of 3D-printed food is a key challenge. Concerns about authenticity, safety and taste quality must be overcome to achieve broad market penetration.

- Technological limitations: Although 3D printing technology is constantly advancing, certain technological limitations still stand in the way. Precision in texture and flavor reproduction must be further developed to meet the standards of conventional food products.

- Need for research and development: Continuous research and development is required to advance the technology of 3D printing of food and open up its wide range of applications.

The future of 3D printing in the Food Industry: Tailored Nutrition, Sustainability and Creative Freedom

The future of 3D printing in the food industry promises to be transformative, with far-reaching implications for the way we produce, consume and experience food. At the heart of this development is the increasing individualization of food. People will be able to customize their diets down to the smallest detail to suit their individual needs and preferences, whether due to allergies, diets or personal preferences.

A key aspect of the future of 3D printing of food is sustainability. This technology will help reduce the environmental footprint by enabling precise dosing of ingredients, using alternative sustainable filaments and minimizing food waste.

In the food service industry, 3D printing will enable unprecedented creative freedom. Chefs will not only be able to develop innovative flavor combinations, but also create stunning visual presentations that take the dining experience to a new level.

In addition, 3D printing of food will accelerate product development. New food products can be quickly adapted and optimized to respond to changing consumer preferences and trends. This will make the food industry more agile and improve market responsiveness.

Overall, increased research and development in the field of 3D printing for food will lead to innovative applications and materials that will further expand the possibilities of this fascinating technology.