3D printing on a grand scale – additive manufacturing of large-volume metal components

The Macro-SLM process enables the production of individual metallic components with extremely high build rates in cubic meter dimensions. In contrast to deposition welding, it offers all the design freedom of powder bed-based 3D printing.

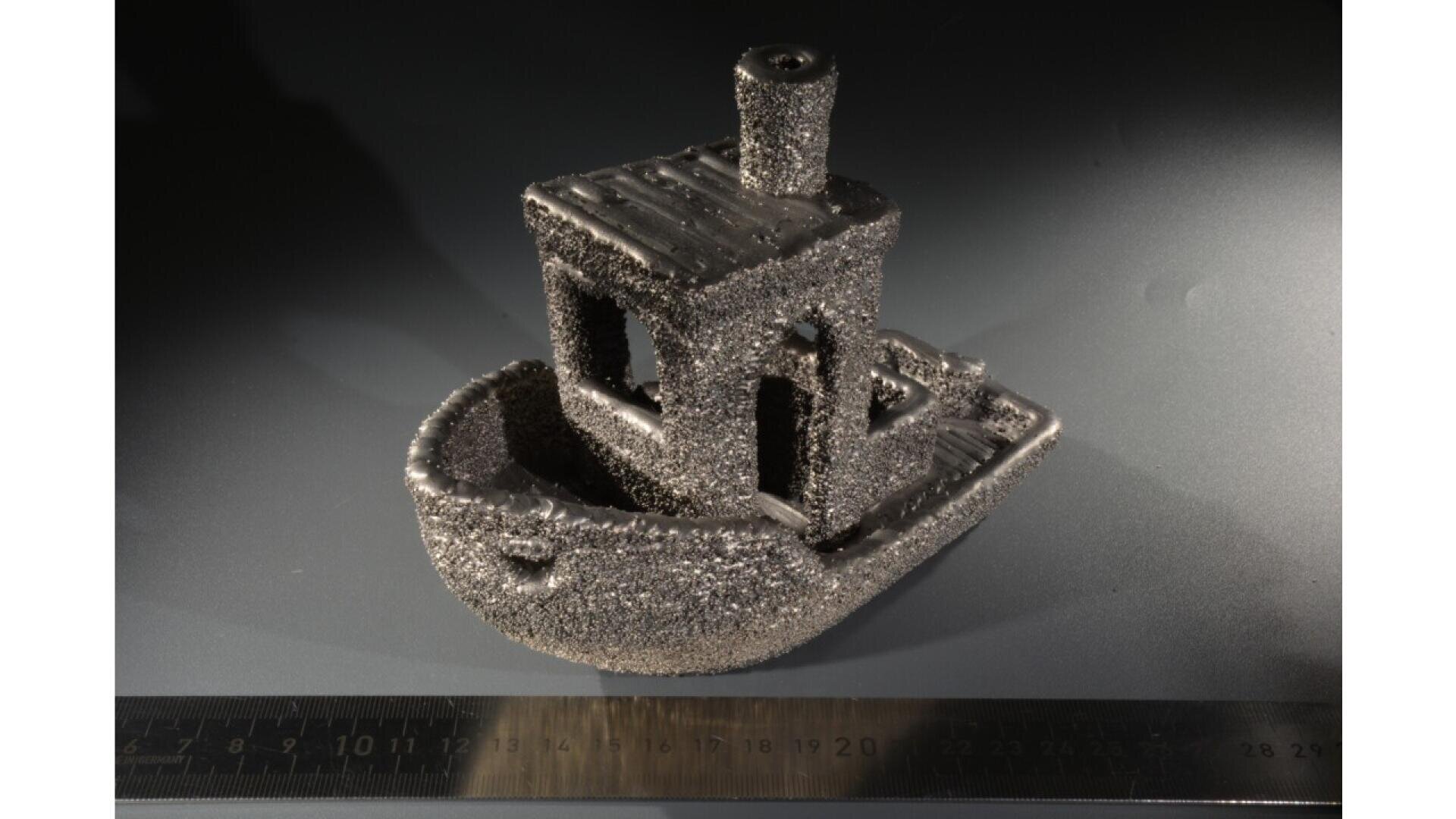

The Macro-SLM process developed at the Laserinstitut Hochschule Mittweida (LHM) is a further development of the established laser powder bed-based 3D printing of metal components (also known as SLM or L-PBF) for the additive manufacturing of large-volume components. By increasing the laser power, spot diameter, layer thickness and powder grain size, structural resolutions in the millimeter range are generated instead of the usual micrometer range. This in turn enables an enormous increase in the build rate of up to 10 kg/h. It is therefore similar to the structure resolutions and build rates of deposition welding. However, the supporting powder bed offers the advantage of being able to realize more complex geometries. Macro-SLM thus combines the advantages of both worlds: high freedom of design and high productivity at the same time. With the new process, large-volume and complex components close to the final contour can be produced quickly and cost-effectively. The required functional surfaces are realized by subsequent machining. This makes it a genuine alternative to metal casting and milling.