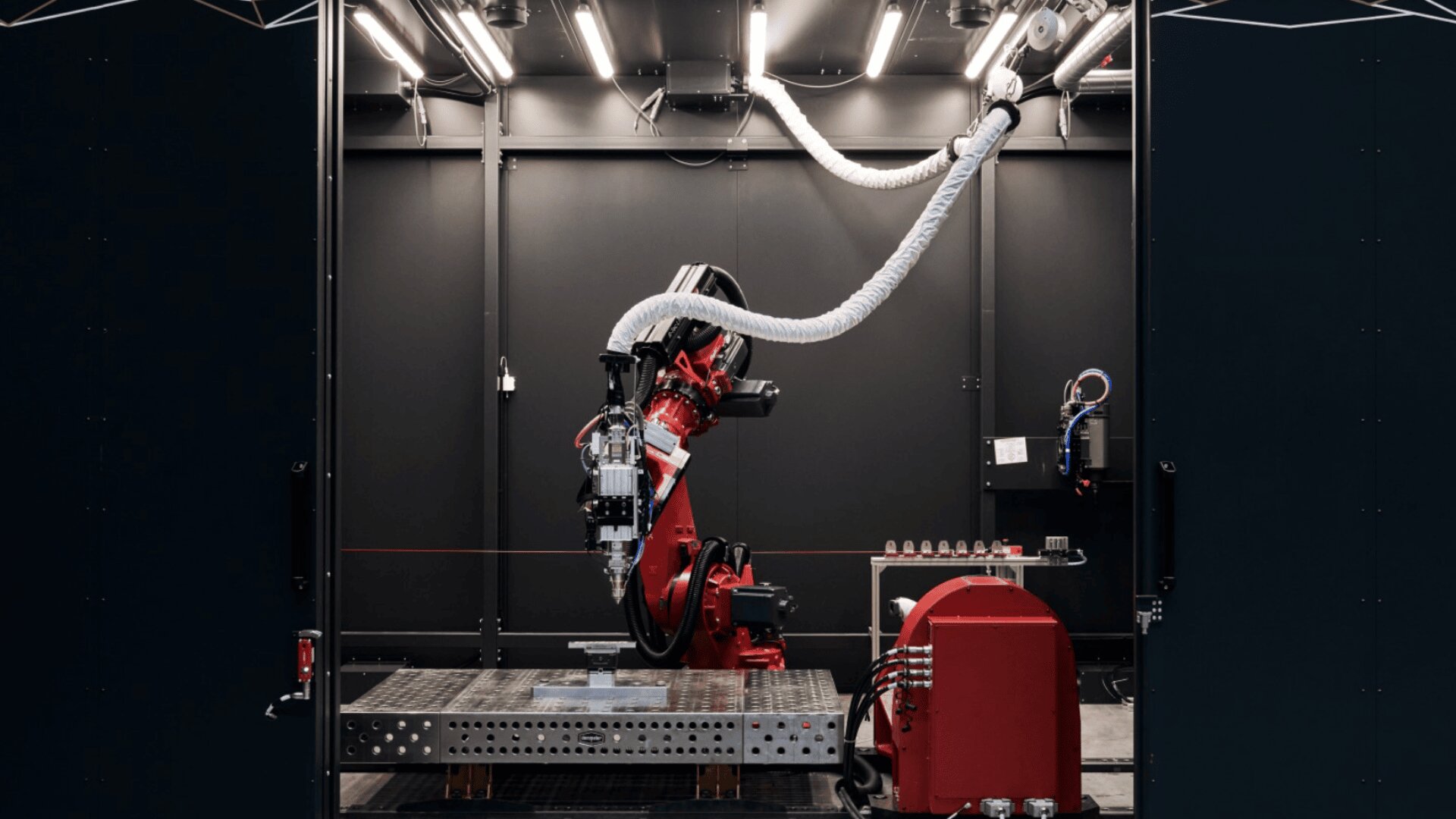

Additive manufacturing + robotics - More sustainable manufacturing through hybrid repair and automated support removal

In their talk TOOLCRAFT AG will shed a light on their innovation of hybrid repair (LMD + machining) for large and small components in series within a robot cell

toolcraft AG manufactures high-end precision parts and components. As a pioneer for future-oriented technologies, the company implemented additive manufacturing as early as 2011, mapping the entire additive value chain in metal. The robotics division was also established over 1O years ago and designs, programs and manufactures customized robot solutions according to individual customer requirements. The latest new development is a hybrid LMD robot application that is used for combined additive and subtractive processing. The laser nozzle enables the repair of damaged or warn components by selectively applying material. Compared to new production, this approach not only saves costs, but also reduces the amount of material used compared to new production. lt also opens up the possibility of realizing previously impossible material combinations and further machining them in a single clamping operation. In the area of L-PBF, toolcraft has also achieved another breakthrough. The manual and previously very time-consuming process of support removal has been optimized by innovative automation using dry ice blasting. This solution reduces the workload on employees, leads to high-quality results and significantly increases the efficiency of additive manufacturing.

Language of presentation: GER

(English translation will be provided on site)

Speakers (1)