Technology Platforms for Modular (Production) Plants and 3D Printing

Sustainability is a core element of EVONIK OPERATIONS GMBH's strategy. With Next Generation Solutions and Next Generation Technologies, we are actively contributing to the realization of the UN sustainability goals.

We do not produce car tires or mattresses, no pills and no animal feed. And yet Evonik is present in these final products – just like in many others too. Often, it's the small quantities we contribute, but it's exactly those that make the difference. Because with Evonik, tires become fuel-savers, mattresses more elastic, pills more effective, and animal nutrition healthier. That's specialty chemistry. And in that field, we're among the best in the world.

Sustainability is a core element of our strategy. With Next Generation Solutions and Next Generation Technologies, we actively contribute to the realization of the UN Sustainable Development Goals. By using modular plant construction and 3D printing of process equipment, we implement Next Generation Technologies in the form of technology platforms.

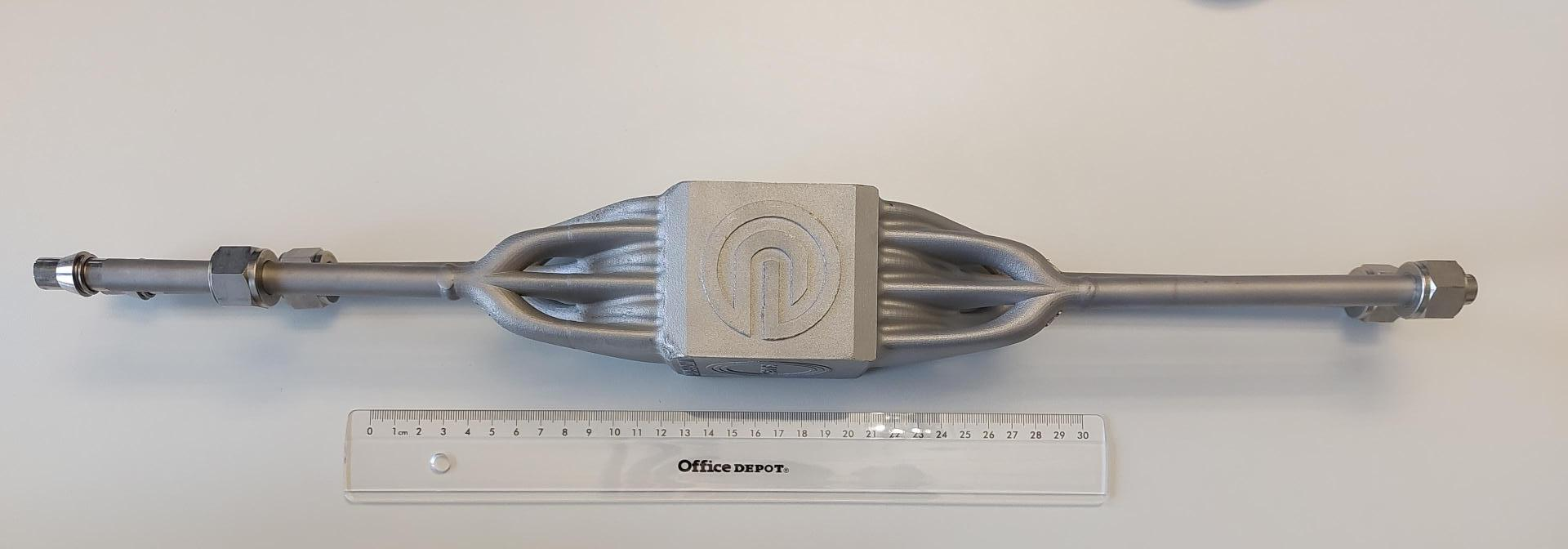

Modular plant concepts increase flexibility and efficiency in the process industry through standardized interfaces and the plug-and-produce principle. This technology promotes the integration of new process technologies, as demonstrated in the MACBETH project with a catalytic membrane reactor. Furthermore, modular approaches are ideally suited for the use of 3D-printed components.

3D printing is revolutionizing industries such as medicine and automotive manufacturing with custom-made, complex components. However, in the context of the chemical industry, strict safety standards and regulations (e.g., the Pressure Equipment Directive) must be taken into account, which Evonik has been intensively engaged with for over five years. The publicly funded project 3D-PROCESS, in collaboration with partners Siemens, Ineratec, and the Karlsruhe Institute of Technology, can be cited as an example.

Presentation language: GER

(English translation will be provided on site)

Speakers (1)

Dr. Senada Schaack

Head of Evonik Competence Center SAM 3D – Simulation & Additive Manufacturing