The interplay between a digital tool chain and stable additive parameters for industrial DED-Arc applications

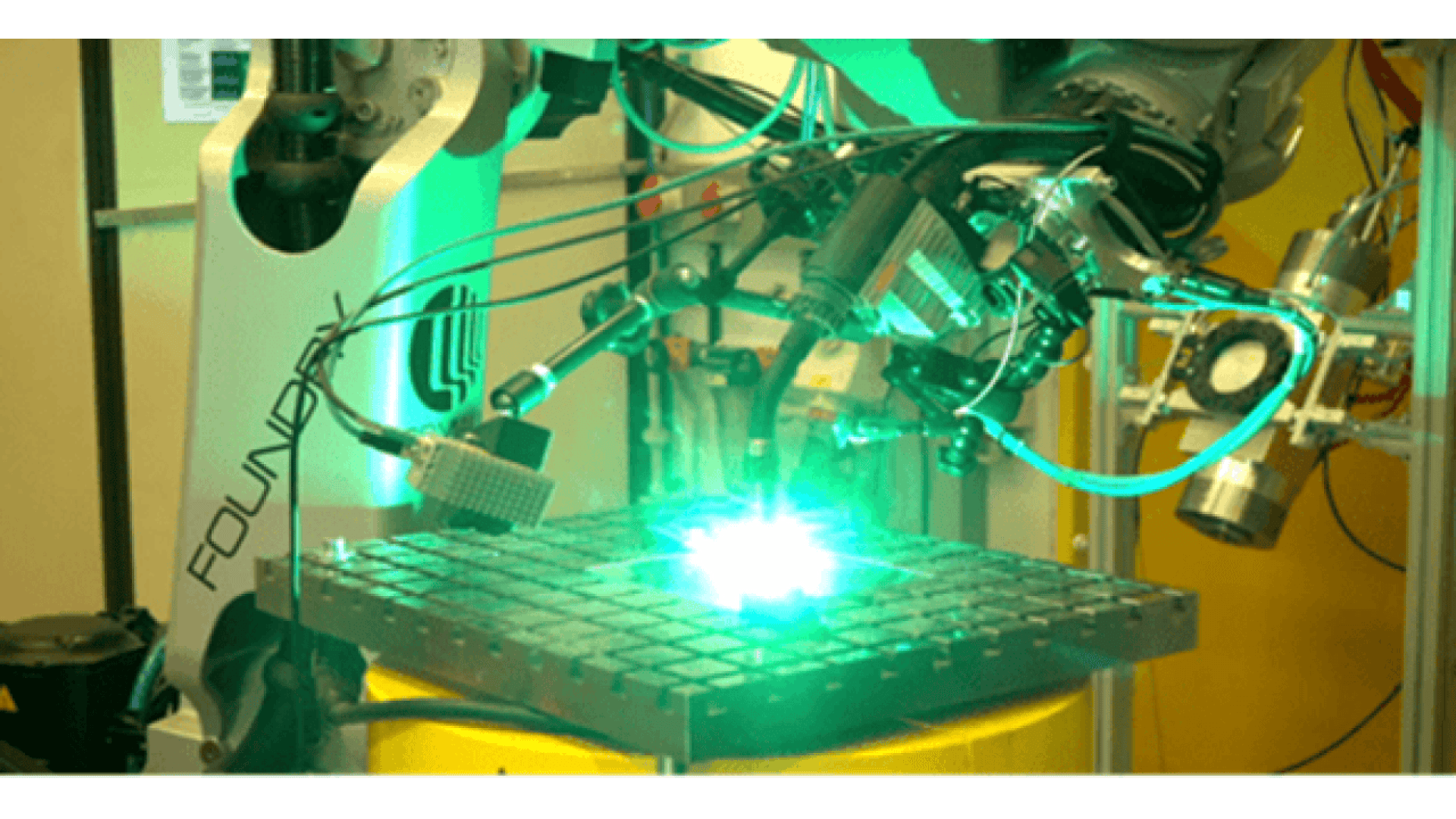

FRONIUS & SIEMENS TECHNOLOGY present a dynamic relationship between a digital tool chain and additive parameters in the context of Directed Energy Deposition with Arc (DED-Arc) technology

This presentation delves into the dynamic relationship between a digital tool chain and additive parameters in the context of Directed Energy Deposition with Arc (DED-Arc) technology - by combining powerful CAM software with industrial experience in additive welding. The objective is to address the challenges faced in industrial Additive Manufacturing, where the integration of virtual process planning with process technology is crucial. The complexity of parameters often hinders easy usage, resulting in rework, errors, and delays. Automation in process planning and control is necessary to overcome these challenges.

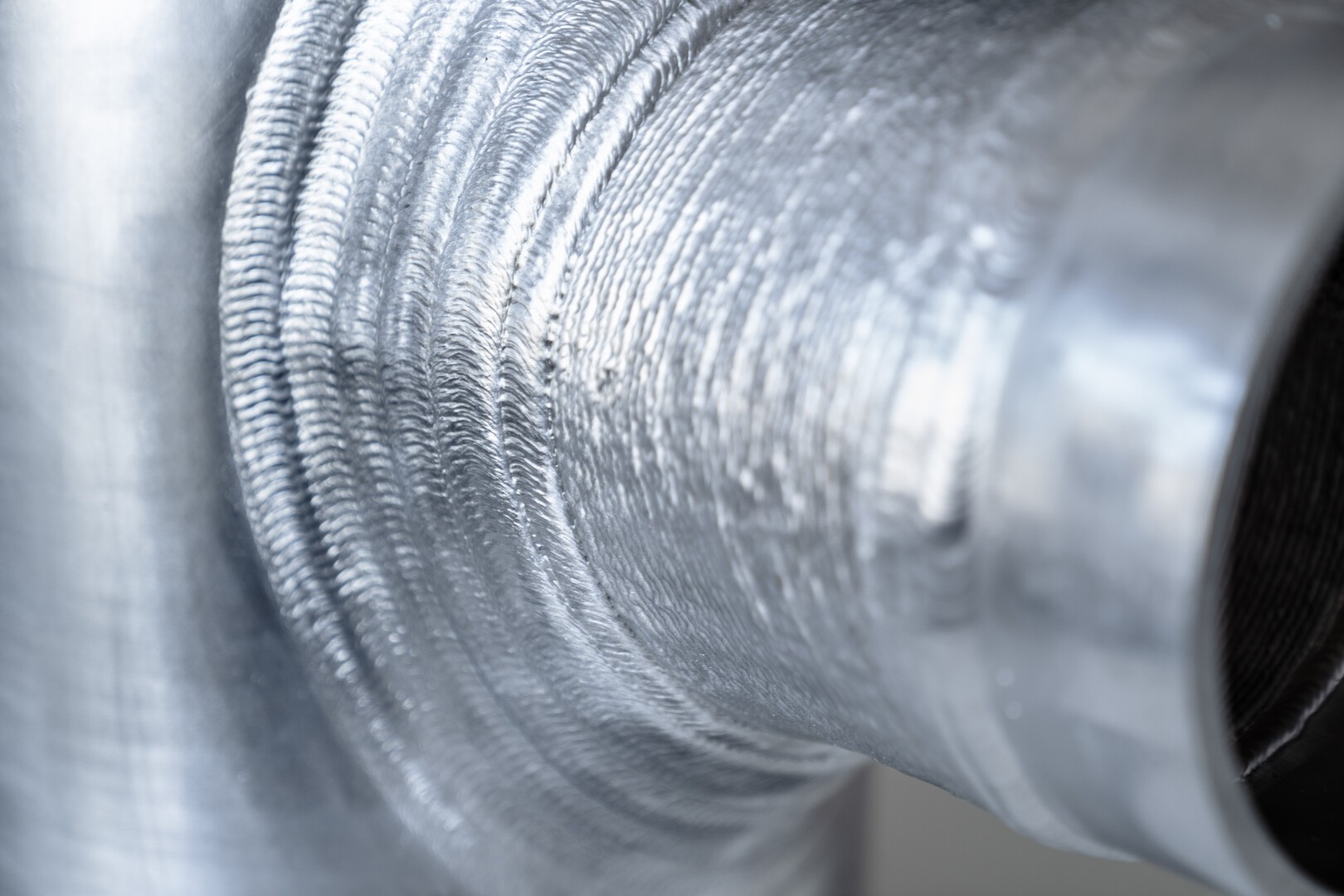

Also, a concrete example of a complex pipe branch is showcased to demonstrate the importance of integrating the additive welding process into the broader end-to-end Additive Manufacturing workflow. This includes component design, determination of welding process parameters, build preparation, machine and robot simulation, and advanced process control. By showcasing a complete and integrated workflow, this presentation emphasizes the significance of bridging the gap between virtual planning and process technology to enhance industrial productivity.

The presentation also highlights the need for continued research and development in additive manufacturing, providing an outlook on future applications and activities. The aim is to tackle complex manufacturing processes and drive industrial productivity to new heights.

Presentation language: GER

(English translation will be provided on site)