Two-stage process for 3D printing of paste-like materials

3D Printing Conference powered by STRATASYS: We are looking forward to Christoph Doerffel's (Steinbeis Innovationszentrum Automation in Leichtbauprozessen) presentation at the anniversary edition of Rapid.Tech 3D 2024.

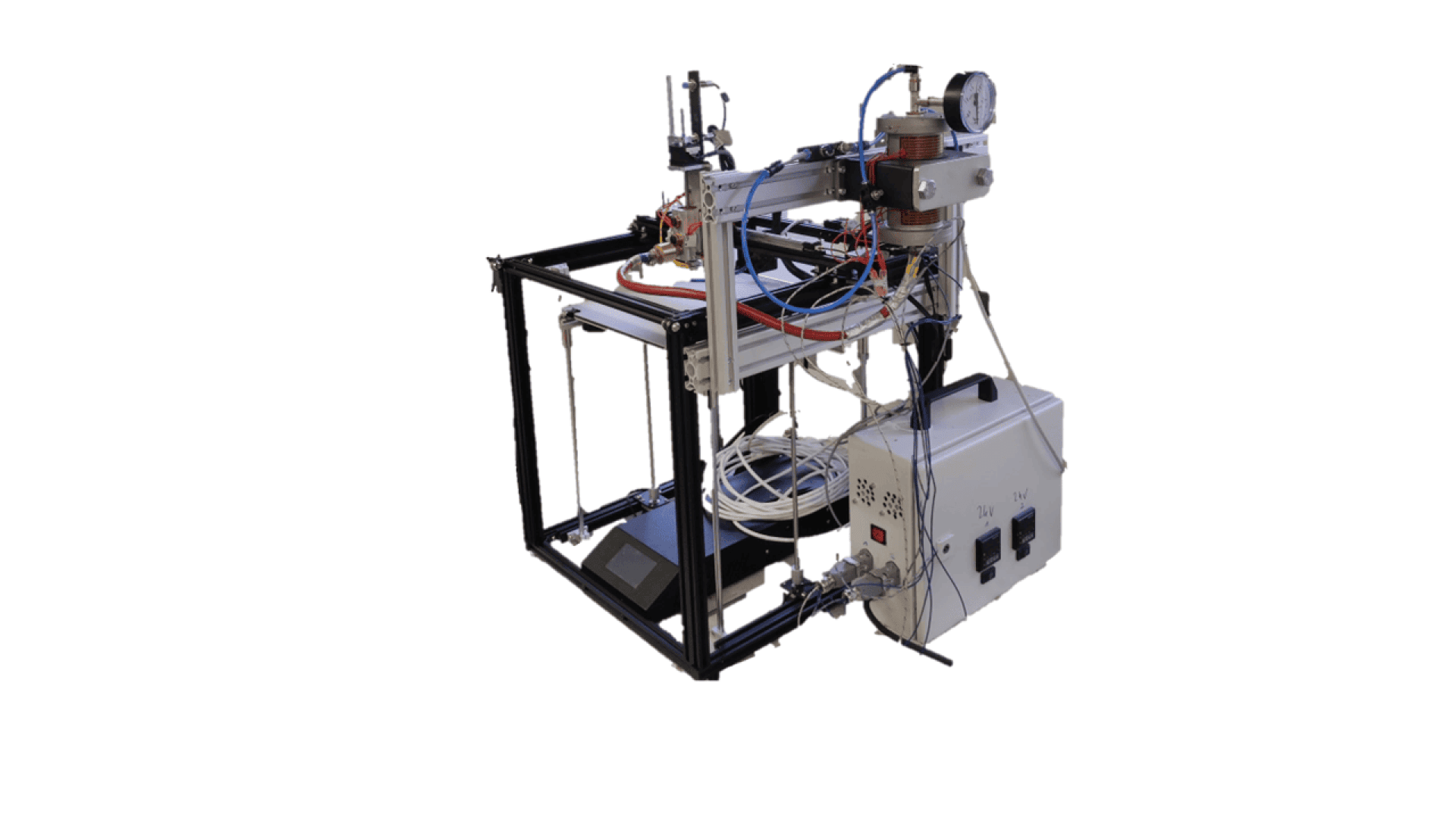

Heated piston dispensers are often used for 3D printing of pasty materials in free-space processes, which are very similar to the FDM process. These can precisely dispense a limited supply of material, if they are driven by stepper motors and spindles. Major limitations of these systems are the size of the material supply and the inhomogeneous thermal state of the mass during plasticising. These problems can be solved by plasticising the material separately from dosing. In separate plasticising, the material can be completely heated to a defined temperature while a small supply is discharged in the print head. The reduced material supply in the print head reduces its weight and thus improves its dynamics. The transfer of the melt from the plasticising unit to the print head is fully automated during the printing process, therefore the filling process is fast and reproducible.

However, separating the systems also increases the complexity of the main system and makes it necessary to introduce new process parameters. These parameters control both the plasticising of the material and the interaction of dosing and plasticising as well as the material transfer between the systems and the integration of the sub-processes into the main printing process.

The presentation will use a use case to illustrate the design and combined operation of the units.

Speakers (1)