Filament-based metal and ceramic 3D printing

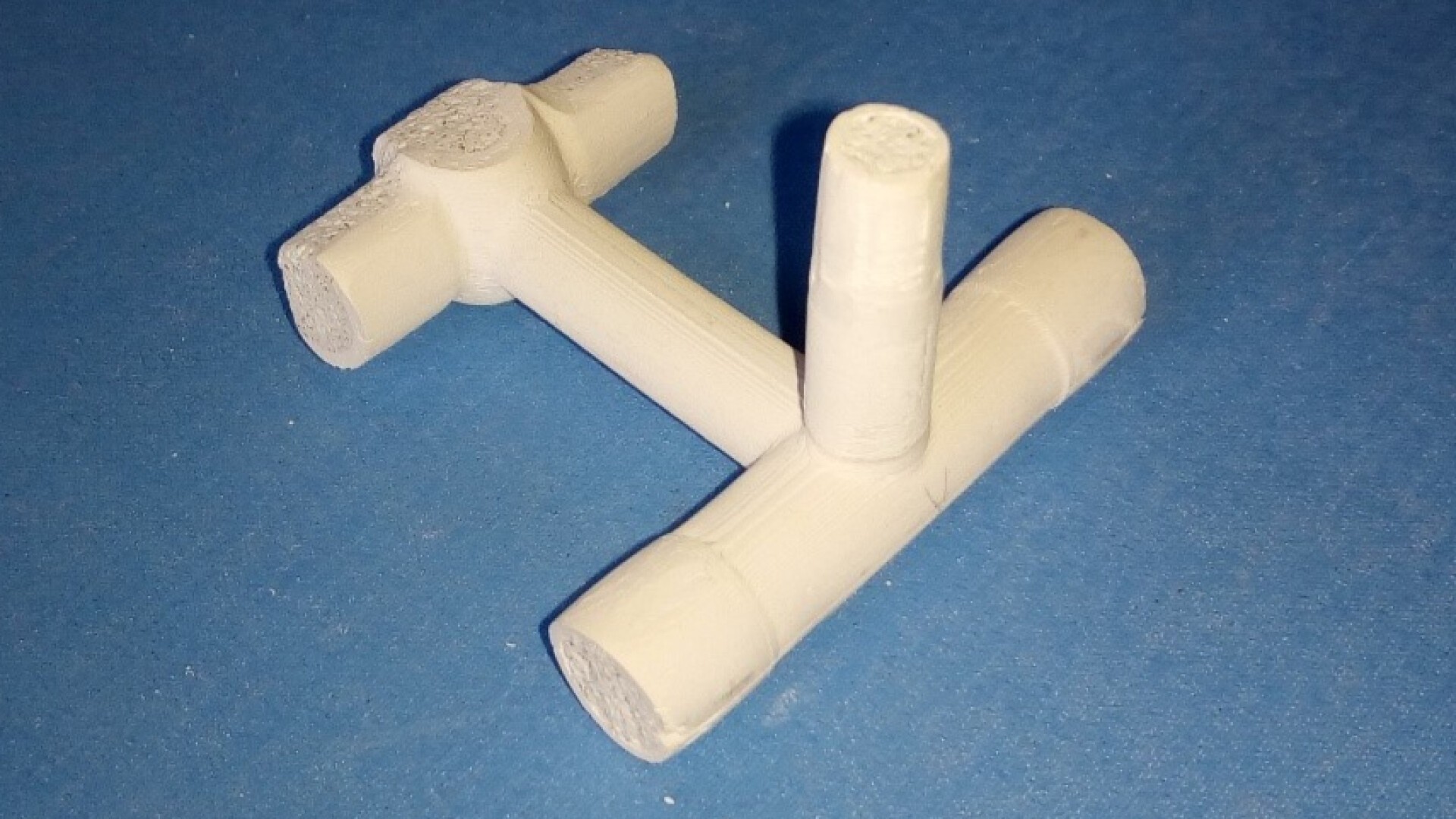

We have expanded our 3D printing systems to include a flexible, filament-based printer. This can be used to process filaments of various ceramics or metals: models, ceramic investment casting cores and even metallic functional parts.

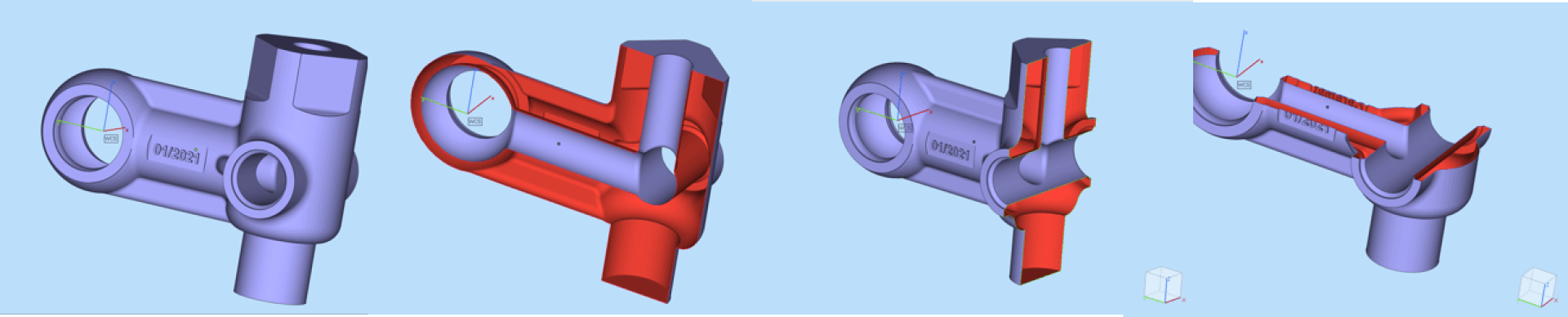

As part of rapid.tech 2025, we will be discussing the in-house development of a multi-material printer for the filament-based 3D-production of metal parts and ceramic cores for investment casting.

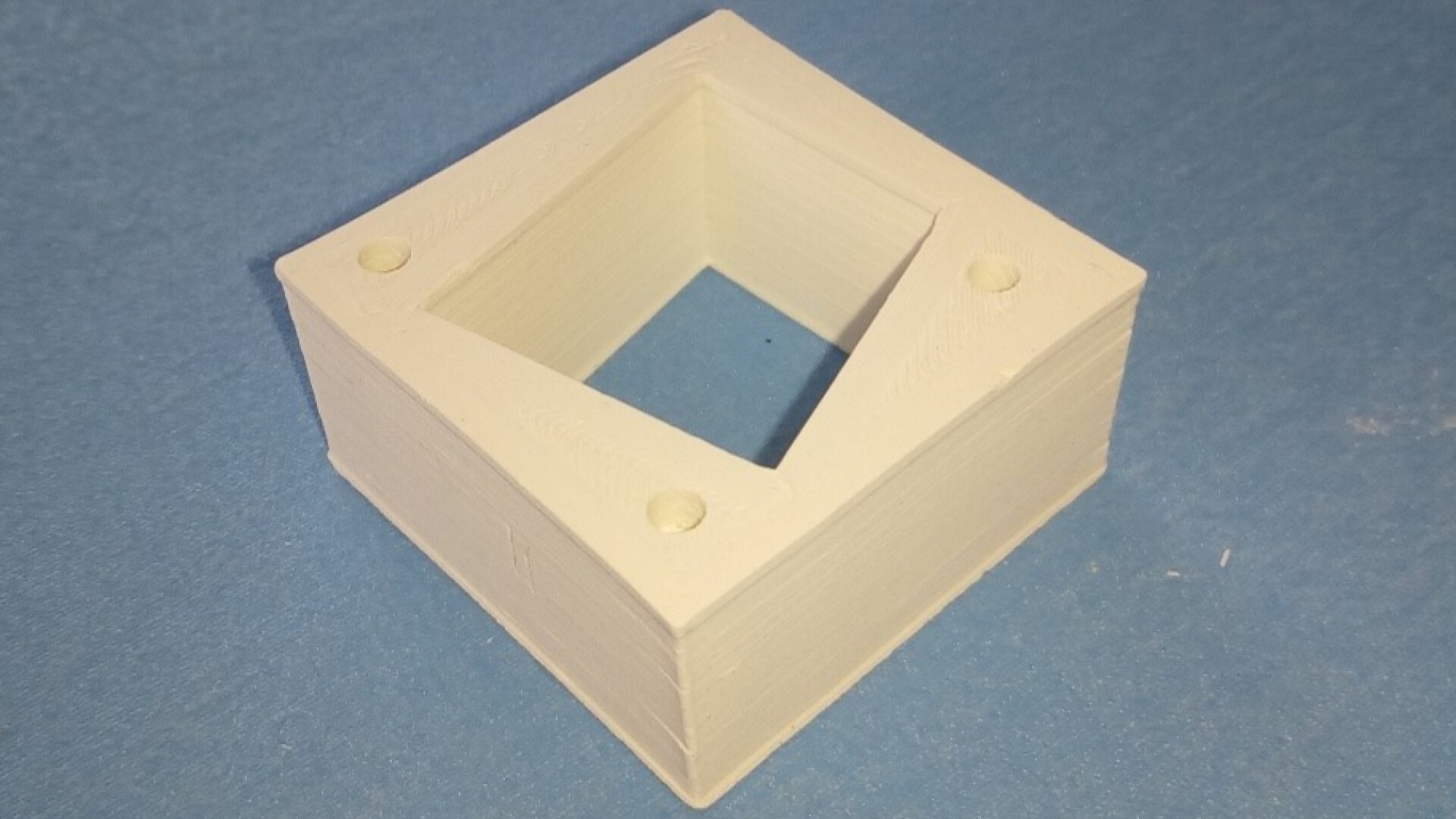

Filament-based 3D printing of metals or ceramics is particularly challenging due to the particularly demanding due to the thermal post-treatment. The technical challenge increases all the more when 3D-printed ceramic cores are used in lost wax models in investment casting. In addition to process-stable, precise production and taking into account the effects of shrinkage, the ceramic core has to be removed after the metal casting, removed without leaving any residue and without damaging the metal part.

As part of an R&D project, proof was demonstrated that filament-based 3d-printing of metal and ceramic components can be used for prototypes and small batches.