Advancing heterogeneous catalysis by adopting 3D metal printing

CATIP B.V. will report on the advantages of 3D metal printing for the performance of (heterogeneous) catalytic reactors, as well as practical examples of the application of 3D metal printing reactors in the environmental and energy sector.

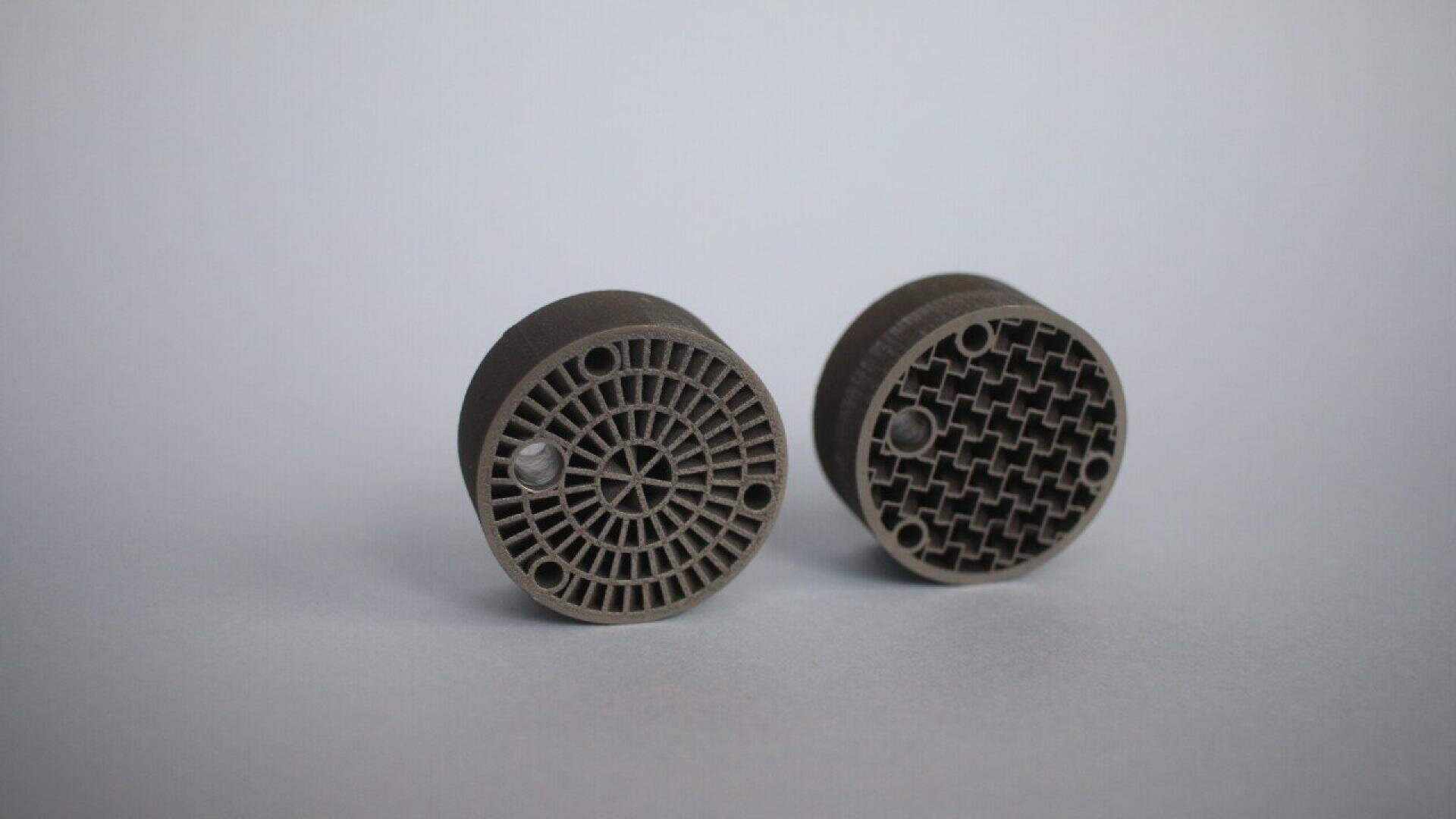

Already in the early nineties the benefits of metal catalytic reactors were recognized. The technology of production of these sintered metal reactors however resulted in reactors of elevated weight and commercial application was therefore not achieved. Two of the co-founders of CatIP recognized already in 2010 that the technology of 3D metal printing would improve their production and filed patent applications in the field of air purification and hydrogen carriers. The first concept reactor was printed as early as 2014, and further development commenced in 2016. This formed the basis for the foundation of CatIP (2020), developing the technology in different market verticles such as: aur purification, bulk chemical production & the energy sector. Here we show the developments from lab- to commercial industrial scale. The benefits of the reactor technology, improved heat & mass transfer, resulting in process intensification (better catalyst utilization, longer catalyst lifetime, smaller reactor size) will be presented supported by relevant examples. Finally, an outlook will be given how the field is expected to develop in the next decade.

Presentation language: ENG

Speakers (1)