Rapid remanufacturing and spare part production on site

METROM Mechatronische Maschinen GmbH has a unique position on the market. The applications of Metrom machines are as diverse as their configurations.

The world's first mobile repair factory for hybrid machining (Fig. 1) is based on developments by the Saxon mechanical engineering company Metrom. The technology, which is housed in containers, enables additive and subtractive manufacturing processes to be carried out in a single set-up. This means that repairs or spare parts production can be carried out directly on site in power plants, chemical plants, in shipbuilding, in port logistics or even in mines that are often far away. This significantly minimizes costly downtimes.

The heart of the mobile repair factory is the Pentapod. This combines the precision and rigidity of stationary machine tools with the freedom of movement of a robot. This invention, which led to the founding of the company in the early 2000s, has given the company a unique position on the market.

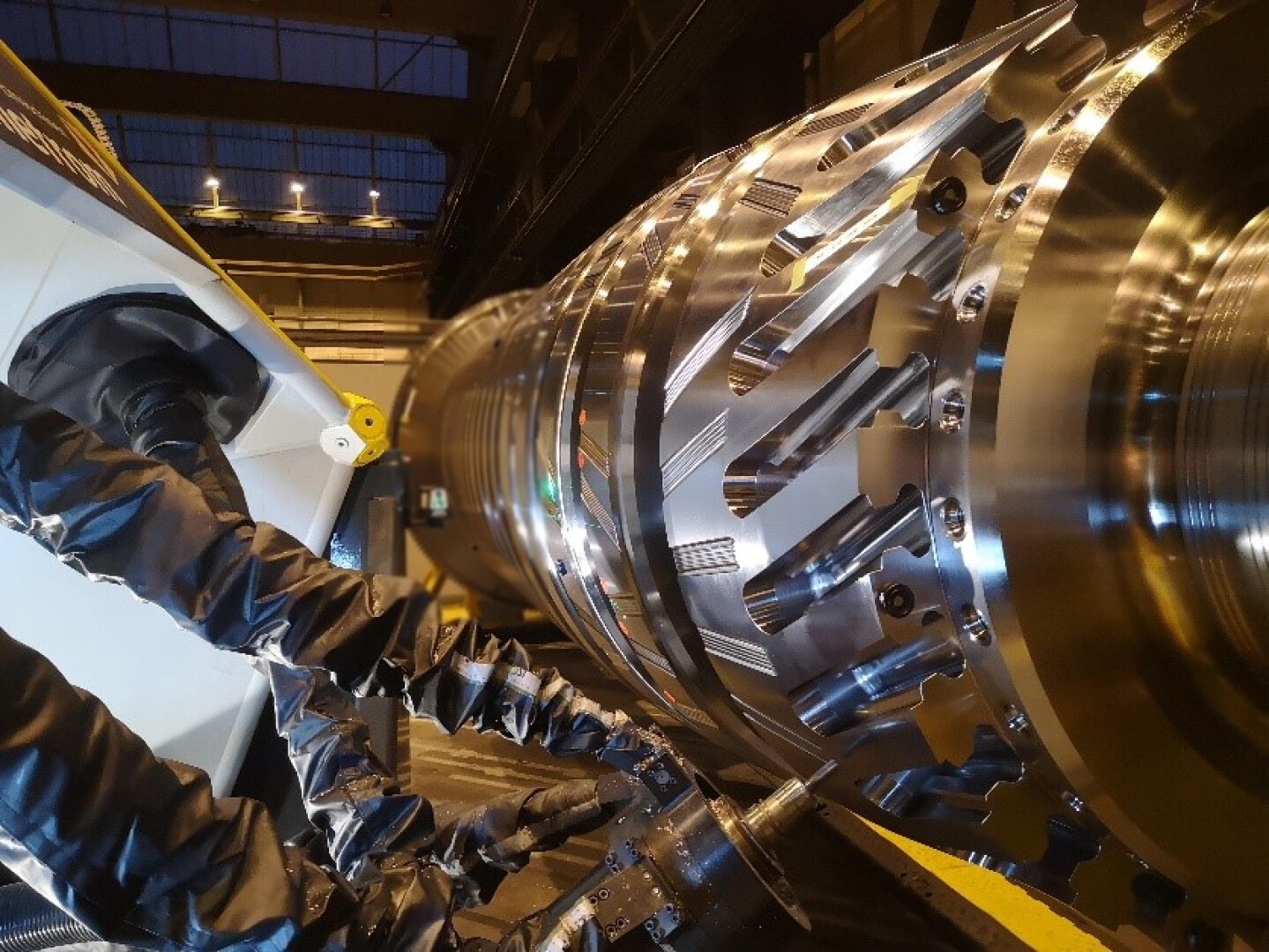

In this concept, the component is the pivotal point. While in conventional machine tools the workpiece is brought into the correct position, in the mobile Metrom systems the tools move around the component. This enables maintenance and repair work to be carried out on turbines (see Fig. 2), generators or other large-scale systems.

The applications of Metrom machines are as diverse as their configurations. They are used in the automotive industry as well as in energy and agricultural engineering, in the production of components (Fig. 3) and in many other sectors.

Presentation language: ENG

Speakers (1)