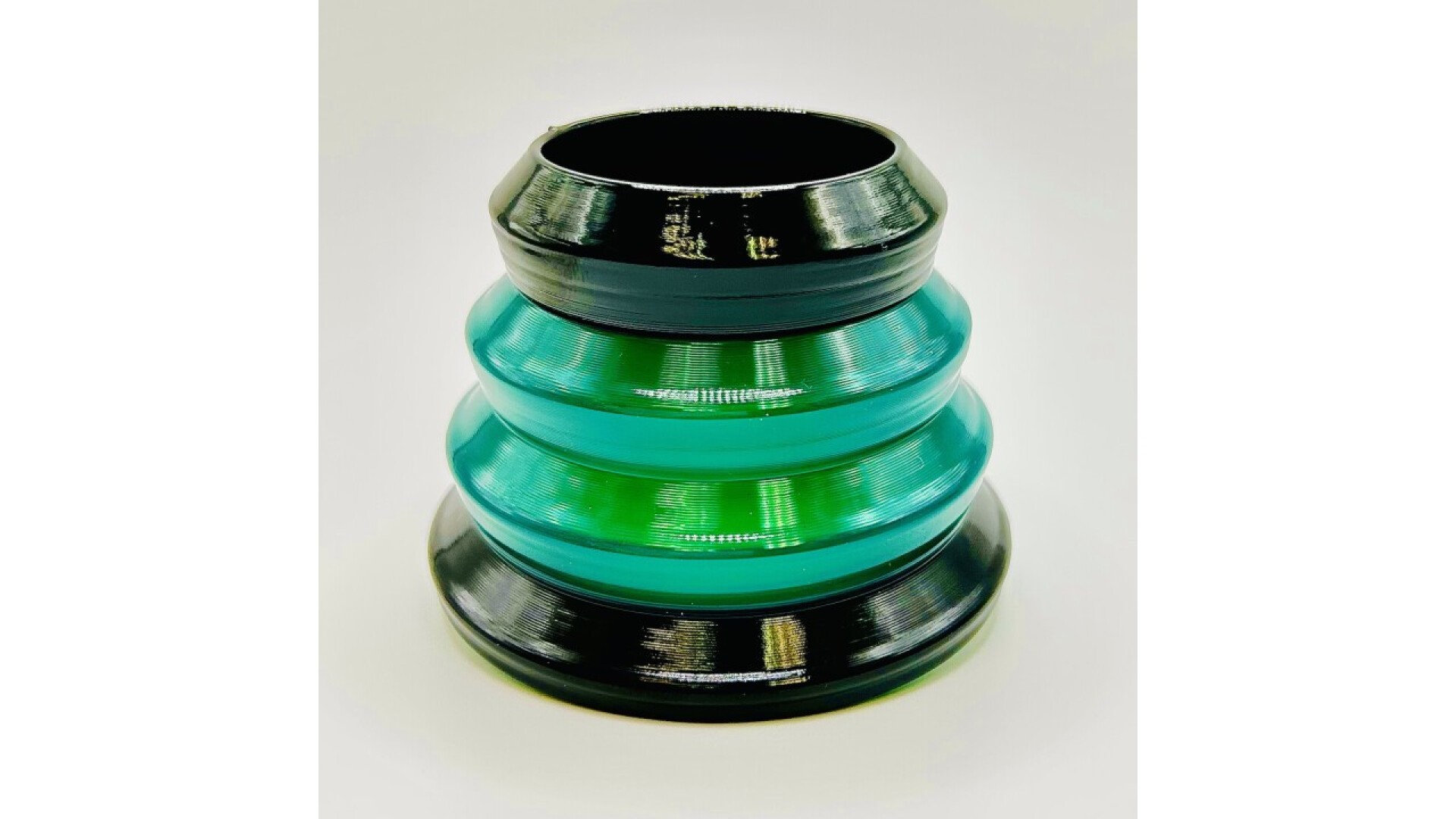

RX-AM Platform to print industrial grade elastomeric parts

PU materials offer a wide range of properties for AM applications. C3DM develops formulations for industrial dispensing systems and the Chromatics RX-AM platform. With 20 elastic variants from Shore A 50 to Shore D65, we offer solutions for vibration damping, sealing and environmental stability.

PU materials are well known and allow for a large variety in formulation to achieve the desired material properties. Through liquid processing

they can be cost efficiently synthesized in quantities relevant for the AM market. C3DM creates formulations achieving the desired material

properties while being processable in available industrial dispensing equipment or at our RX-AM Platforms.

Elastomer applications often involve vibration dampening, sealing against pressured media or stability against environmental influences over

an extended period. This dictates material properties such as tensile properties, media resistance or elastic rebound. For traditional

manufacturing processes like injection or compression molding or CNC-machining from a semi-finished product, material already exists.

Additive manufactured solutions that are to compete with traditional solutions need to achieve the same functionality meaning the material

properties must be comparable.

Chromatic 3D Materials offers 20 different elastic PU materials in a Shore Hardness between Shore A 50 and Shore D65 with media stability in

hydraulic oil, typical fuels, liquid and vaporous aqueous environments including weather and UV resistance grades.

Other materials such as EPDM are currently in development

Presentation language: GER

(English translation will be provided on site)

Speakers (1)