Camera-based measurement and control of the contact tip to work distance in wire arc additive manufacturing

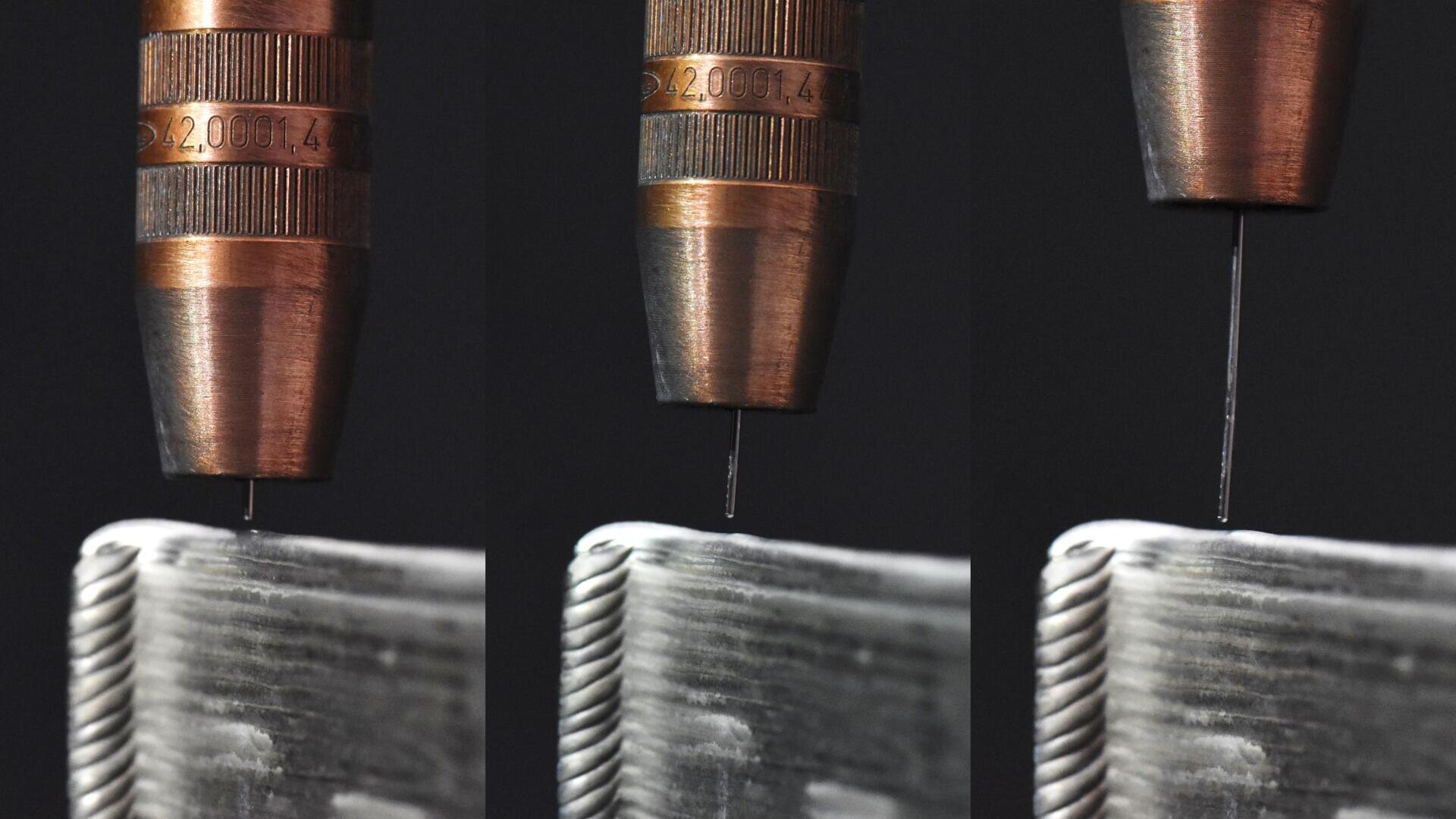

In wire arc additive manufacturing, the distance between the welding torch and the part has a noticeable influence on part quality. By keeping it constant, consistent shielding gas coverage can be ensured, and welding spatter or pro-cess interruptions can be avoided.

In wire arc additive manufacturing, the distance between the welding torch and the part has a noticeable influence on part quality. By keeping it constant, consistent shielding gas coverage can be ensured, and welding spatter or process interruptions can be avoided. In this work, images are taken by a welding camera and processed by a deep learning model to extract distance information. Subsequently, a novel control strategy is developed, which skips or repeats layers in order to keep the distance constant during the manufacturing process. The validation shows that the geometric dimen-sional accuracy of the produced components can be improved by this strategy. Furthermore, process interruptions or collisions between the welding torch and the component due to incorrect slicing settings can be avoided. In addition, the control system determines the actual layer height in the component, which can be used to carry out future slicing pro-cesses more precisely and thus reduce the number of control interventions.

Vortragssprache: ENG

Sprechende (1)