Empirical calibration method for the thermal simulation of Cu47Ti34Zr11Ni8 single tracks in laser powder bed fusion

Advancements in additive manufacturing of Bulk Metallic Glasses using Laser Powder Bed Fusion are explored, focusing on the Cu-Ti-based alloy Vit101. Utilizing high-speed pyrometry & thermal simulations on single tracks, the understanding of the processing and thermal cycling of Vit101 is enhanced.

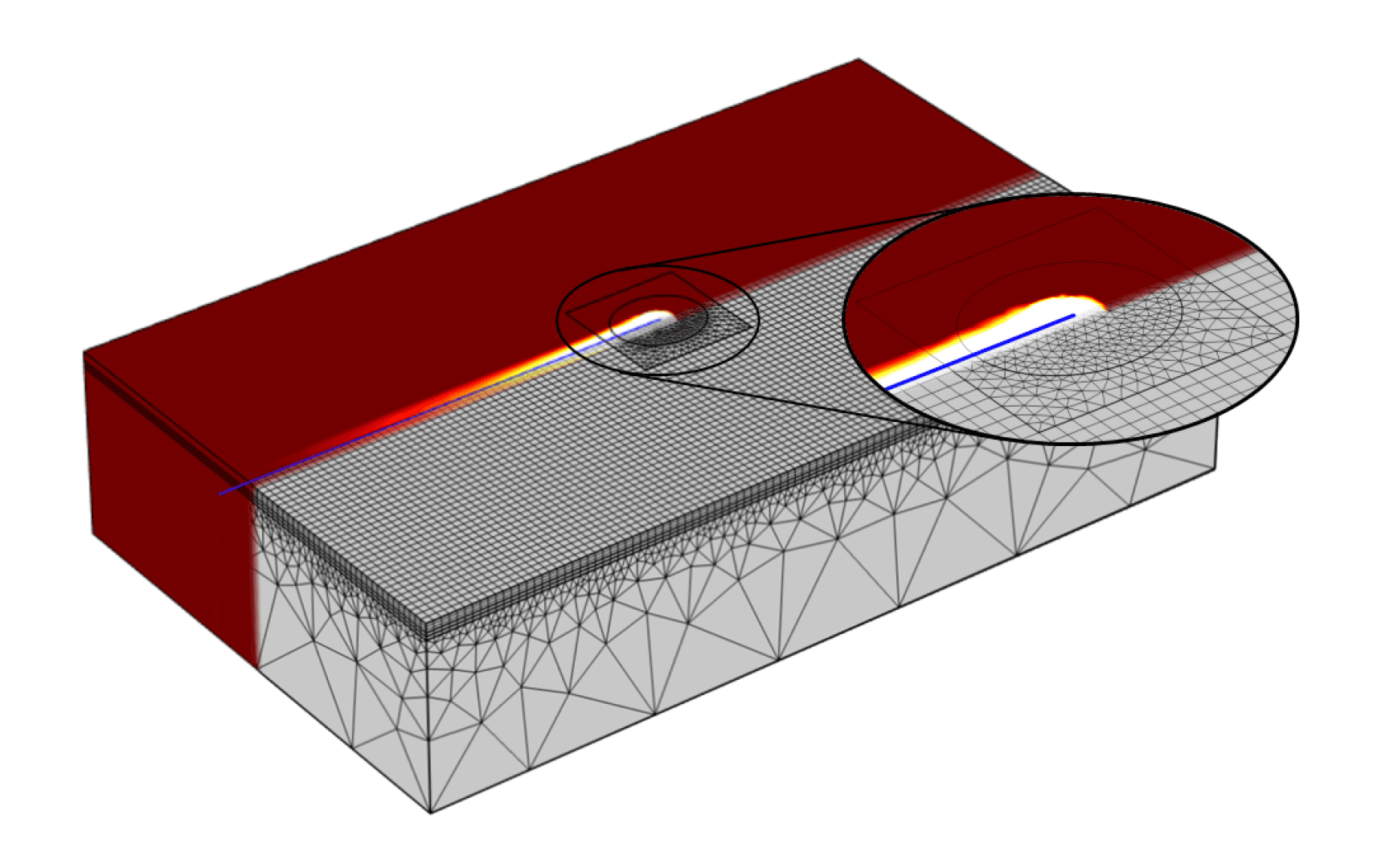

Bulk metallic glasses (BMGs) are materials that, due to their amorphous microstructure, offer a unique combination of high strength, hardness, and elasticity, making them attractive for various applications. Using Laser powder bed fusion (PBF-LB/M) enables overcoming the current limitations of BMGs in size and shape imposed by traditional manufacturing methods such as casting. Despite its potential, challenges such as porosity, (nano-) crystallization, and impurities affect the mechanical performance of additively manufactured BMGs. This study focuses on the Cu-Ti-based alloy Vit101, known for its higher strength and improved cost-effectiveness compared to Zr-based BMGs. In-situ high-speed pyrometry and thermal simulations of single tracks are employed to enhance the understanding of processing and controlling the thermal cycling of Vit101. The proposed experimental calibration is performed through an off-axis integration of the pyrometer, allowing for in-situ temperature measurements. The acquired data shows sufficient congruence with the simulated cooling profiles. Minimal cooling rates in the range of 104 K/s were measured and simulated above the glass transition temperature indicating a large leeway for further development of glass-forming alloys. Scan track widths are evaluated for validation resulting in minor deviations between 0.47 % and 3.17 %. However, challenges emerge at high scanning speeds, leading to higher deviations attributed to balling phenomena which are not considered in the numerical model.

Vortragssprache: ENG

Sprechende (1)